Flow Level Pressure

Oxygen Analyser Guarantees Quality and Safety for Heat Treatment Processes

Oct 20 2013

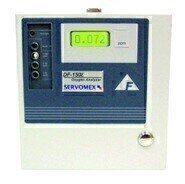

Utilising an advanced coulometric sensing technology that delivers exceptionally accurate and stable oxygen analysis, the Servomex (UK) DF-150E protects batch quality and significantly improves plant efficiency for a range of reflow application processes.

Accurate to ±3% of reading / 0.5% of measurement range, the DF-150E is highly suitable to control O2 levels in surface mount soldering operations in reflow PCB ovens, which must be O2-free if the soldered joint is to be permanently sealed. An extremely versatile unit, the DF-150E can be configured to operate as a single or three-range analyser to meet specific process needs.

In reflow ovens, heat is transferred to assemblies by radiation using Nitrogen (N2) to establish an O2-free environment that minimises oxidisation of surfaces to be soldered. The DF-150E uses non-depleting coulometric E-sensor technology to ensure accuracy with no sensor drifting and no false low readings, protecting against oxidisation. This no fail performance is crucial, as a false O2 reading can waste thousands of dollars in scrapped final product, schedule disruption or cause safety issues when using N2 or mixtures using N2 as a blanketing gas.

The DF-150E's non-depleting technology enables the O2 sensor to cope with short time exposure to ambient air, with options for temporarily disabling the sensor to enable longer exposure to ambient air - a capability not possible with traditional electrochemical sensors, where extended exposure to air quickly damages the cell.

The DF-150E is factory calibrated and reduces cost of maintenance with a five-year sensor warranty that requires only an annual SPAN calibration and no programmed cell replacement. With just a single instrument calibration per year, the reduced maintenance costs and its peerless stability have found favour with furnace manufacturers, quality product managers, process engineers and product development engineers alike.

Every DF-150E is custom configured under ISO-9001 controls to meet the customer’s precise specifications and calibrated to standards traceable to NIST and operated for several days to ensure flawless out-of-the-box performance. The analyser also delivers near-instantaneous response to O2 change – typically taking less than 10 seconds to read 90% of a step change.

The flexibility of the DF-150E means it can be easily integrated into multiple zone sample systems using a manual or automatic sequencing system. This makes it ideal for OEM furnace manufacturers who supply analysers as an option or as standard for the end-user; heat treatment contractors; and on-site or laboratory processes providing treatment for end products in-house.

The DF-150E offers users a range of configuration options that enables the analyser to be built to their particular measurement requirements. Choices include CE Certification, a choice of Outputs, Flow Alarm, Sample Pump and Remote Sensor options. A unique acid gas sensor option also neutralises trace levels of acid gases in the sample including Carbon Dioxide (CO2), Hydrogen Sulphide (H2S), Nitrogen Oxide (NOX) and Sulphur Dioxide (SOX).

Digital Edition

PIN 25.2 Apr/May

May 2024

Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector - Advancements and...

View all digital editions

Events

Jul 10 2024 Birmingham, UK

Thailand Oil & Gas Roadshow 2024

Jul 11 2024 Rayong, Thailand

Jul 20 2024 Denver, CO, USA

Jul 21 2024 Cape Town, South Africa

Jul 24 2024 Bogata, Colombia