Fuel analysis

New autosampler brings a new level of speed, precision and simplicity to fuel analysis

Jun 24 2024

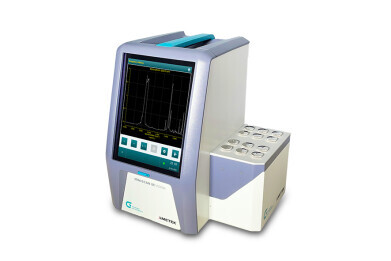

Grabner Instruments recently released its latest advancement in fuel testing: the addition of the AS Vision (ASV) Autosampler to the renowned MINISCAN IR Vision Fuel Analyser. This state-of-the-art combination sets a new benchmark for speed, accuracy, and convenience in the comprehensive analysis of gasoline, jet fuel, and diesel.

The MINISCAN IR VISION is celebrated for its high-speed, compact, and robust fuel analysis capabilities. It measures over 100 fuel parameters and components, making it an indispensable tool for fuel blending, quality inspection, and compliance verification directly at the point of sale. Now, with the integration of the AS Vision Autosampler, the process of fuel analysis is more efficient and reliable than ever before.

The MINISCAN IR VISION is preconfigured to measure more than 100 fuel parameters, ensuring comprehensive fuel analysis. This includes key properties like Octane and Cetane numbers, distillation, vapor pressure, and many others. The analyser performs compound analysis according to ASTM D5845 for oxygenates, ASTM D6277 and EN 238 for Benzene, and EN 14078 for Biodiesel blends, ensuring adherence to global fuel quality standards. A built-in, temperature-regulated density meter guarantees accurate and stable fuel density measurements. Utilising Partial Least Square (PLS) analysis and sophisticated chemometric models in accordance with ASTM E1655, the device analyses thousands of data points for highly accurate predictions. The MINISCAN IR VISION operates with calibration data strictly adhering to the highest quality standards, leveraging a unique database of real samples collected and analysed by SGS®.

The AS Vision Autosampler significantly enhances the MINISCAN IR VISION's capabilities by enabling rapid and continuous testing of up to 12 samples with a single press of a button. Developed to achieve the highest sample throughput, the ASV ensures efficient and reliable fuel analysis via FTIR. The temperature-regulated, piston-based filling system of IR Vision prevents sample agitation and degradation, maintaining sample integrity from bottle to measuring cell. When paired with a liquid chiller, this system further preserves sample quality.

A thermally optimised connection between the ASV and the IRV prevents sample degradation, ensuring confident FTIR fuel analysis. User-Friendly Interface: The full-colour, industrial touchscreen of the IR Vision allows for simple programming of the ASV's workload. User profiles facilitate quick parameter training and fast sample group changes, accommodating samples from different regions. Designed for true portability, the combined IRV + ASV system is ideal for use in various settings, including import inspections (for fuel adulteration), pipeline terminals, tank farms, mobile laboratories, and independent testing labs.

With the integration of the AS Vision Autosampler, the MINISCAN IR VISION Fuel Analyser sets a new standard in the field of fuel analysis. This powerful combination ensures the highest level of accuracy, efficiency, and reliability, providing unmatched performance in fuel quality testing.

Digital Edition

PIN 25.5 Oct/Nov 2024

November 2024

Analytical Instrumentation - Picturing Viscosity – How Can a Viscometer or a Rheometer Benefit You? - Sustainable Grease Formulations: Evaluating Key Performance Parameters and Testing Method...

View all digital editions

Events

Jan 20 2025 San Diego, CA, USA

Jan 22 2025 Tokyo, Japan

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China