Analytical Instrumentation

New Multi-Element Analysis Technique for Lubricants

Aug 01 2014

Engines and other machinery must often operate under extreme conditions such as high temperature environments and heavy loading, and manufacturing of lubricants is no exception.

Additive packages are used in lubricant manufacturing to help prevent possible mechanical failure of process systems due to excessive wear or heat. In order for additive packages to be most effective, precise elemental analysis is required to ensure the correct blend of organometallics—compounds containing metal-carbon bonds that work to prevent wear. Critical elements to monitor within the additive package include phosphorous, zinc, and calcium, all of which are critical for prolonged performance.

Over time, friction and corrosion of engine components can introduce metals into the lubricating oils and impact equipment performance. Contamination can also come from outside sources such as dirt or leakage. Monitoring for suspect metals in lubricating oils can help determine whether servicing or maintenance of the system is needed. Identifying trends and detecting trace amounts of wear metals such as iron and chromium can help to reduce maintenance and prolong engine or machine life.

The HD Maxine Analyzer from XOS (USA) offers an inexpensive, easy-to-use alternative to ICP-AES (inductively coupled plasma atomic emission spectroscopy) for detection of multiple elements in additive packages. The HD Maxine is suitable for use in both laboratory and production applications. There is minimal sample preparation and the analysis is non-destructive. Simply pipette or pour 1 ml of sample into the test cup and measure with the press of a button. The HD Maxine provides precise, multi-element results in ten minutes or less, completely eliminating the need for a lengthy and expensive ICP-AES procedure.

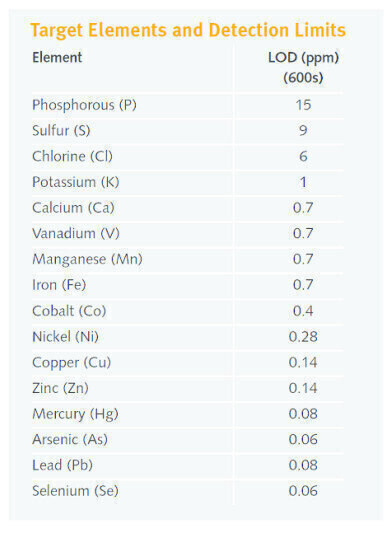

The HD Maxine is powered by high definition XRF (HDXRF) technology, delivering exceptionally low levels of detection for multiple elements. HDXRF uses doubly curved crystal (DCC) optics to enhance measurement intensities, capturing x-rays from a divergent source and redirecting them into an intense focused beam on the sample surface. The use of multiple DCC optics enables multiple select-energy excitation beams that efficiently excite a broad range of target elements in the sample. This technique eliminates x-ray scattering background under the fluorescence peaks, greatly enhancing detection limits and precision.

Contact XOS to discuss your testing needs and learn more about the XOS line of portable, lab, and process analysers for either single or multi-element detection, delivering unrivaled precision at the push of a button.

Digital Edition

PIN 25.2 Apr/May

May 2024

Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector - Advancements and...

View all digital editions

Events

Jul 10 2024 Birmingham, UK

Thailand Oil & Gas Roadshow 2024

Jul 11 2024 Rayong, Thailand

Jul 20 2024 Denver, CO, USA

Jul 21 2024 Cape Town, South Africa

Jul 24 2024 Bogata, Colombia