Analytical Instrumentation

GC Analysis of Inhibitors & Extraction agents in Butadiene by direct injection

Dec 09 2015

The current standard test method for determining Total Inhibitor Content (TBC) of Light Hydrocarbons is ASTM D1157: a labour intensive method that requires evaporation of the sample. To eliminate the evaporation step Da Vinci Laboratory Solutions developed the Liquefied Gas Injector that allows a direct injection of the liquid gas samples such as Butadiene into a GC inlet.

GC-LGI Configuration

Download the application note for a description of a gas chromatographic analysis of inhibitors and extraction agents in Butadiene using the DVLS Liquefied Gas Injector (LGI). The GC is configured with the LGI, an on-column injection port, a solvent vapour exit and Flame Ionization (FID) detector.

The light ends of the matrix are vented via a solvent vent valve. The compounds with higher boiling points are retained on a precolumn. After closing the vapour exit valve the retained compounds are separated on the analytical column.

Analytical Results

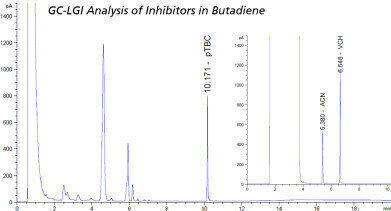

Originally the LGI was introduced for the analysis of oily residues in Liquefied Petroleum Gases (LPG) and approved as ASTM D7756 & EN 16423. To mimic the Butadiene matrix the inhibitor compounds (pTBC, ACN and VCH) are dissolved in a mixture of C3 & C4 and in C5.

In first instance all compounds are tested on the non polar column commonly used for residue analysis. The results show that pTBC can be very well separated from the C3/C4 matrix of LPG.

Measuring ACN in the C3/C4 matrix on the same non polar column does not separate ACN from the matrix. Therefore this compound is analysed on a WAX type column. The test results show that this polar column is very well able to separate ACN and VCH, even from a C5 matrix.

The analytical results demonstrate that the LGI-GC technique is a safe and accurate alternative to the existing Butadiene test method ASTM D1157. Controlled handling of Butadiene cylinders, in combination with the on-column GC injection, reduces health and safety risks for the analysts.

Application range

The DVLS Liquefied Gas Injector offers laboratories a safe and proven GC standard for the following applications:

- Oily residues and light contaminants in LPG (ASTM D7756, EN 16423)

- Hydrocarbon composition of LPG (ASTM D 2163, ISO 7941)

- Sulfur compounds in liquefied petroleum gases

- Desulfurization additives in LPG: DIPA, MEA & DEA

- Inhibitors, additives and Dimers in Butadiene: ACN, ρTBC, Butadiene Dimer

- N2, CO2, H2S and Hydrocarbons in Unstabilised Gas Condensate.

Download the application notes for a complete description of the various analyses performed with the DVLS Liquefied Gas Injector.

Digital Edition

PIN 25.2 Apr/May

May 2024

Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector - Advancements and...

View all digital editions

Events

Jul 10 2024 Birmingham, UK

Thailand Oil & Gas Roadshow 2024

Jul 11 2024 Rayong, Thailand

Jul 20 2024 Denver, CO, USA

Jul 21 2024 Cape Town, South Africa

Jul 24 2024 Bogata, Colombia