Analytical Instrumentation

Automate the Analysis of Active Oxygen by the Fast Peroxide Analyser

Jan 18 2017

Hydrocarbon streams such as Styrene, Isoprene and Butadiene may form thermally unstable peroxide types on exposure to air. Accurate monitoring of reactive peroxide traces is required to prevent hazardous plant conditions. The Fast Peroxide Analyser developed by Da Vinci Laboratory Solutions is an automated, fast and precise alternative to traditional wet chemistry methods such as ASTM D2340 and E299.

Automated Analysis

The DVLS Fast Peroxide Analyser (FPA) is based on an HPLC stack including a quaternary pump, an automated sample introduction system, an UV detector and instrument control processing software. The analysis of Peroxide, as active Oxygen, is based on the oxidation of Iodide by Peroxide. Two reagents, Acetic Acid in Propanol and Sodium Iodide in Propanol are mixed, resulting in a stream of acidified Iodine solution in Propanol. The sample is injected into this stream.

Next step is to lead the liquid stream through a heated inert reaction coil. Iodine is formed under temperature controlled conditions inside the dedicated reaction oven developed by Da Vinci. After passing the reaction coil the HPLC UV detector spectrophotometrically determines the formed Iodine, which is proportional to the level of peroxide.

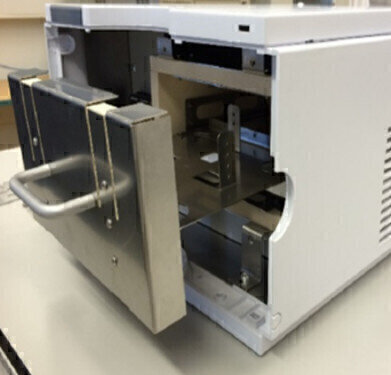

Dedicated Reaction Oven

The reaction oven developed by Da Vinci enables an optimal heat distribution to the reaction coil. The oven design matches the HPLC modules thus allowing stacking of the oven between the autosampler and the detector.

The module contains two heating plates; one plate is situated directly above and the other one is located directly below the reaction coils. To stabilise the heating cycle and to prevent a temperature overshoot an air fan is installed at the back of the module.

The outlet of the reaction coil is placed in a cooling compartment to ensure a cooldown of the reagents and product before they enter the UV detector. The oven maximum temperature is 225°C (437 °F).

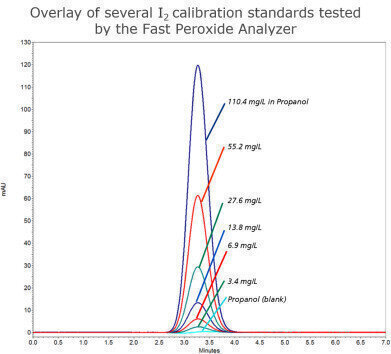

Performance Check

Linearity was determined by measuring the prepared concentration range of I² in Propanol. Each concentration was measured in triplicate. The test results show that the linearity of the FPA is set at R² ≥0.999 over a range of 3 – 100 mg/L I² in Propanol, which is equivalent to 0.2 – 6.3 mg/L active oxygen.

The LOD for I² is measured at 0.46 mg/L at a prepared I² concentration of 13.8 mg/L and 1.23 at a prepared concentration of 55.2 mg/L. Comparing the measured LOD values with the target of ≤ 3 demonstrates the excellent performance of the Fast Peroxide Analyser. Download the flyer to find all details on the performance specifications of the Fast Peroxide Analyser or contact Da Vinci.

Key Benefits of the Fast Peroxide Analyser

- Safe alternative to traditional wet chemistry analysis methods

- Standard HPLC modules contribute to a precise determination of Peroxide

- Fast analysis of only seven minutes

- Modular design saves benchspace

- Excellent performance.

Digital Edition

PIN 25.2 Apr/May

May 2024

Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector - Advancements and...

View all digital editions

Events

Jul 10 2024 Birmingham, UK

Thailand Oil & Gas Roadshow 2024

Jul 11 2024 Rayong, Thailand

Jul 20 2024 Denver, CO, USA

Jul 21 2024 Cape Town, South Africa

Jul 24 2024 Bogata, Colombia