Safety

Liquid Analysis: Precision, Accuracy and Instrument Safety

Jun 20 2012

In petroleum industry, analytical accuracy and precision are critically important for routine process and quality control for everything ranging from additives to contaminates. Regulation limits for airborne pollutants due to burning fossil fuels continue to decrease as well in allowable limitations. The tighter regulations require not only high stable instrumentation but also very reproducible results, thus making wavelength dispersive X-ray fluorescence (WDXRF) an ideal solution.

But one of the largest concerns for laboratories using XRF is the safety of their instrument during liquid analysis. An accident in liquid analysis can damage an XRF system costing days of productivity downtime and thousands of dollars in parts and service.

Instrument Safety

Thermo Scientific ARL PERFORM’X spectrometer used in this analysis is a 4200 watt system. This system is configured with 6 primary beam filters, 4 collimators, up to nine crystals, two detectors, helium purge and our 5GN+ Rh X-ray tube for best performance from ultra-light to heaviest elements thanks to its 50 micron Be window. This new X-ray tube fitted with a low current filament ensures an unequalled analytical stability, performance and safety. Its unique LoadSafe design includes a series of features that prevent any trouble during sample pumping, loading and analysis. Liquid cassette recognition prevents any liquid sample to be exposed to vacuum by mistake. Over exposure safety automatically ejects a liquid sample if X-ray exposure time is too long.

The Secutainer system protects the primary chamber by collecting any drops in a specially designed container, easily removed and cleaned by any operator. For spectral chamber protection, the ARL PERFORM'X uses a helium shutter designed for absolute protection of your goniometer during liquid analysis under helium operation. In the "LoadSafe Ultra" configuration, a special X-ray tube shield provides total protection against sample breakage or liquid cell rupture.

Results

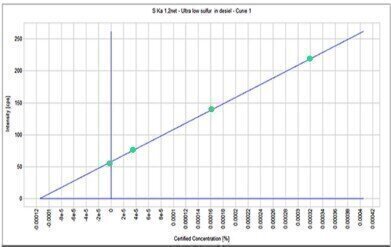

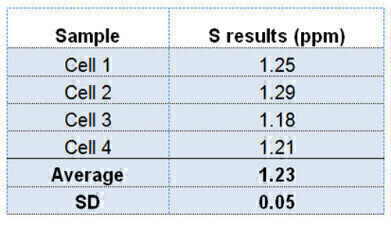

Many elements are considered important for petroleum process control. One of the most requested is sulfur. Sulfur can range from sub-ppm to 5% in petroleum samples. Fortunately, WDXRF is able to analyze S at these varying concentrations using a sample calibration curve corrected for self absorption (Fig. 2/Table 1).

Conclusion

Petrochemical regulations are becoming strict, demanding lower levels of quantification for key elements such as sulfur, nickel, vanadium, lead. Compliance with various norms: ASTM D2622, ASTM D4927, ISO 20884, requires high sensitivity and stability to ensure content conforms to regulatory limits. The advanced ARL PERFORM’X WDXRF provides advantages over traditional methods, like excellent repeatability and resolution. An innovative way of presenting the liquid sample with an absorbing pad provides excellent limits of detection, particularly for light elements such as sodium and magnesium. Oils can be measured directly without dilution, which significantly reduces sample preparation time and increases speed and throughput of analyses.

Designed for demanding laboratories, the ARL PERFORM’X system offers rapid and precise analysis of up to 84 elements with the highest safety.

More on www.thermoscientific.com

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 08 2025 Birmingham, UK

Apr 08 2025 Kielce, Poland

Apr 08 2025 Ravenna, Italy

Apr 08 2025 Southampton, UK

Apr 08 2025 London, UK