Pour point

Remote, multi-channel, and cost-efficient solution for real-time process measurements

Aug 07 2023

4-IR’s Oberon NIR Process Analyser is a cutting-edge solution poised to revolutionise process analysis in the petroleum related sectors. This state-of-the-art analyser incudes several remarkable features, including remote architecture, multi-channel capabilities and automatic modelling, making it the perfect choice for long-distance, economical and low-maintenance process analysis solutions.

The Oberon NIR Process Analyser stands out with its remote architecture, enabling long-distance measurements while saving costs. Utilising low-cost fibre optics (62.5 /125 micron) and a powerful computer, the analyser can be centrally located in the control room, while up to 12 field units can be positioned remotely at distances of up to 3 kilometres from the analyser. This streamlined setup enables swift channel switching between different streams, reducing acquisition time to less than 15 seconds per channel.

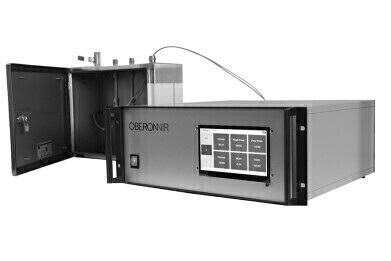

The core of the Oberon lies in its all-in-one analyser box. This compact unit integrates all essential optic parts, including the spectrometer, detector, light source, and multiplexer, along with a powerful computer featuring a touch screen interface. Users can connect an external keyboard/mouse/display for streamlined management, as well as integrated wireless connection. The system offers a clear and user-friendly display, showing either the analysed properties on a panel view or a graphic representation of the acquired spectra.

The Oberon NIR Process Analyser seamlessly integrates cutting-edge AI technology through the ModelGateway software, providing users with automatic calibration of chemometric models. By inputting lab data into the software, the analyser facilitates automated modelling, prediction, and reporting. The predicted concentrations are effortlessly reported to the Distributed Control System (DCS) over Modbus (TCPIP / serial) or OPC, enabling users to make quick and informed decisions. The AI-based solution offers the flexibility to respond to process changes within a matter of hours.

This versatile instrument caters to a wide range of applications across a variety of industries. Some of the key applications include gasoline parameters such as Research Octane (RON, ASTM D 2699), Motor Octane (MON, ASTM D 2700), aromatics, RVP, density, flash point, and pour point, as well as volume percentage or mole percent of paraffins, isoparaffins, aromatics, naphthenes, and olefins. Additionally, it measures common diesel parameters such as specific gravity, viscosity, flash point, pour point, cloud point, and cetane index.

The Oberon NIR Process Analyser is designed to endure harsh conditions, making it a reliable choice for the challenging environments operators in the oil related industry face daily. With the ability to handle flow pressure of up to 60 bar probe pressure and temperatures up to 120 degrees Celsius, the analyser guarantees optimal performance even under extreme conditions.

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 15 2025 Moscow, Russia

Apr 22 2025 Hammamet, Tunisia

Apr 22 2025 Kintex, South Korea

Solar & Energy Storage Summit 2025

Apr 23 2025 Denver, CO, USA

Apr 27 2025 Portland, OR, USA

.jpg)