Analytical instrumentation

Increasing Efficiency, Safety, and Reliability in Refineries with Real-Time Crude Feedstock Analysis

Feb 20 2024

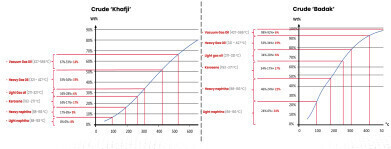

The refining process of crude oil is intricate, heavily reliant on understanding the oil's properties like distillation profile, API gravity, and suphur content. However, challenges such as time-induced variability, alterations during transportation, and uncertainty with opportunity crudes impede accurate analysis. Manual laboratory testing, though common, is hindered by its infrequency and delays. Consequently, refineries often operate below their optimal efficiency, leading to profit losses.

Real-time crude analysis presents a solution to these challenges, offering transformative benefits across various operational aspects:

a. Crude Custody Transfer Verification: Real-time analysis ensures immediate confirmation of incoming crude quality, enabling refineries to comply with purchase agreements and effectively execute production plans. Continuous monitoring of critical quality aspects enhances refinery unit reliability and reduces operational costs. This allows refineries to safely utilise diverse crude sources, including economically attractive Opportunity Crudes, without introducing operational risks.

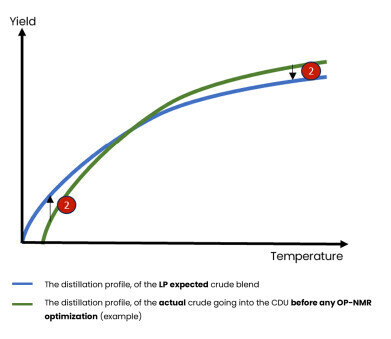

b. Enhanced Safety and Utilisation: Continuous monitoring of crude feedstock enables proactive prevention of operational disruptions in Crude Distillation Units (CDUs). By identifying composition deviations, refineries can mitigate risks such as tray flooding. Real-time analysis also facilitates fine-tuning of operational variables according to the true composition of crude feed, leading to improved efficiency, reduced material waste, and lower carbon emissions.

c. Product Quality and Efficiency: Real-time monitoring at crude blending points enables refineries to optimise feed to distillation units. This optimization stabilises CDUs and upgrading units, improving product blending quality and overall efficiency.

d. Operational Stabilisation: Consistent control of crude feed enhances stability throughout the refining process, improving overall efficiency and product consistency.

e. Dynamic Optimisation: Real-time analysis empowers refineries to adjust production rapidly in response to market opportunities, ensuring competitiveness and economic benefits.

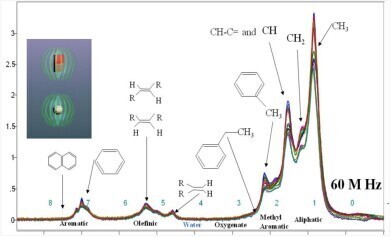

To facilitate real-time analysis, technologies like On-line Process Nuclear Magnetic Resonance (OP-NMR) stand out as superior solutions. OP-NMR technology effectively overcomes limitations of traditional optical analysis methods like NIR and FT-IR. It offers advantages such as non-optical spectroscopy, robust chemometric performance, and simplified sample handling. However, OP-NMR also has limitations, including its inability to observe solids and low sensitivity to impurities.

In summary, the implementation of real-time crude analysis, particularly through advanced technologies like OP-NMR, revolutionises refining operations. By addressing challenges posed by crude oil variability, refineries can achieve optimal efficiency, heightened safety, and increased profitability, ensuring high-quality products and a competitive edge in the market.

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 08 2025 Birmingham, UK

Apr 08 2025 Kielce, Poland

Apr 08 2025 Ravenna, Italy

Apr 08 2025 Southampton, UK

Apr 08 2025 London, UK