Oil analysis

How is Near Infrared Analysis Used for Oil?

May 16 2022

In addition to four main types of hydrocarbons, the average crude oil sample can contain thousands of individual compounds. Scientists rely on advanced techniques such as Near Infrared (NIR) Analysis to detect and quantify these individual compounds. This allows analysts to characterise the unique chemical and physical properties of crude oil samples and make smarter, more informed decisions.

“Petroleum (also called crude oil) exhibits a wide range of physical properties that must be determined before the petroleum is sent to a refinery to produce a variety of products especially the petroleum-based fuels,” writes author James G. Speight in the Encyclopaedia of Analytical Science. “As a result it is necessary to apply a series of standard test methods to determine the refinability of petroleum and to ensure that the fuel products meet the specifications for sales.”

Monitoring parameters of interest

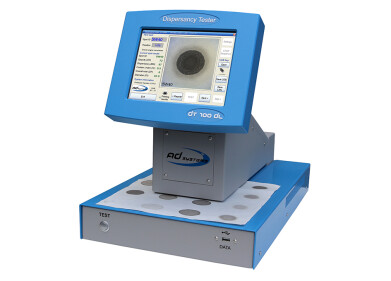

NIR Analysis is widely used at refineries, where decision makers use sampling interfaces to decipher the properties of crude oil. NIR analysers generate real-time data and reveal valuable information about the chemical and physical composition of samples. Data is used to drive chemometrics analysis and monitor parameters of interest, such as butane and benzene concentrations.

‘Online Near Infrared analyser solutions for refinery measurements’ is one of many petroleum-focussed presentations scheduled for the upcoming PEFTEC conference. Mr Hans Buytaert will present the seminar, which will spotlight how NIR analysers are used to monitor hydrocarbon streams at modern refineries.

Calculating Research Octane Rating

Research Octane Rating measures the ability of a fuel to resist detonation when compressed in an internal combustion engine. A Higher Research Octane Rating suggests the fuel is more resilient and can withstand higher compression levels before detonating. Fast and reliable, NIR spectroscopy is used to calculate Research Octane Rating. This helps decision makers select the right fuel for engines and optimise overall performance.

Monitoring reformate

Near Infrared Analysis allows refiners to monitor reformate throughout the blending process. NIR analysers are used to track concentrations of paraffins, isoparaffins, olefins, napthenes and aromatics, a group of primary hydrocarbons known as PIONA.

Quality assurance

From viscosity and acidity to sulphur content, oil manufacturers are bound by strict industry standards when it comes to labelling. NIR Analysis plays an important role in quality assurance and allows manufacturers to check that products meet advertised standards.

Other techniques for oil analysis

The complex physical and chemical characteristics of oil mean analysts rely on a variety of techniques to characterise samples. Find out more about Near Infrared Analysis, as well as other methods such as Gas Chromatography (GC), Time of Flight Mass Spectrometry (TOF) and Differential Scanning Calorimetry (DSC) in ‘Which Instruments & Techniques Are Used for Fuel, Petrochemical & Oil Analysis?’

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 08 2025 Birmingham, UK

Apr 08 2025 Kielce, Poland

Apr 08 2025 Ravenna, Italy

Apr 08 2025 Southampton, UK

Apr 08 2025 London, UK

.jpg)