-

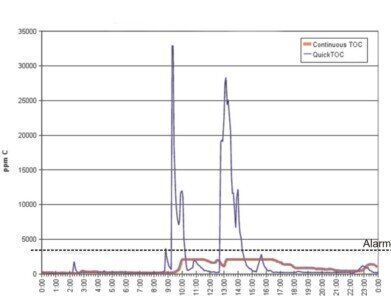

Eventspills at low ranges in condensate application. Batch (QuickTOC) and continuous method (Continuous TOC) in comparison.

Eventspills at low ranges in condensate application. Batch (QuickTOC) and continuous method (Continuous TOC) in comparison.

Measurement and Testing

Did you already know, how you can optimise easily your pure water circuits and save money?

May 15 2014

Guidelines for boiler water quality are getting more stringent. Especially when the boiler pressure is high, the threshold value of Total Organic Carbon (TOC) is not allowed to be exceeded. By use of an online TOC analyser the quality of the boiler feed water and the return condensate can be continuously monitored. Requirements to the TOC analyser are fast and reliable measurements that provide a fast detection of contaminated streams, in order to protect the boiler and downstream pure water system by draining or redirection. In addition, the accuracy of the measurements must be validated by the measurement of a defined solution (standard). This requires a quick calibration and validation function. Also the correct design, construction and implementation of the total TOC analyser installation is of great importance. It includes the right sample take-off point, short sample lines and the correct sample conditioning. Furthermore, the contact time with wetted surfaces has to be minimized eliminating adsorption and memory effects caused by particles and adhesive residues. Therefore, the velocity of the sample in the sample line is recommend at 1 m/s.

LAR's TOC analyser QuickTOCcondensate is especially designed for the condensate application. It uses an multi-loop injection system for a defined sample dosage protecting the sample against contamination from the environment also. The multiple loop injection enables measurements in very low TOC-ranges. The samples are injected into a ceramic reactor that is maintained at a temperature of 1,200 ºC. Due to the ultra high temperature a complete oxidation of all organic carbons to CO2 is guaranteed, no catalysts are required. Afterwards the CO2 is detected with a NDIR-Detector that determined the TOC-content of the sample. LAR's QuickTOCcondensate works with the innovative patented QuickCalibration for easy use and automatic calibration and validation – even by remote control.

In addition, the analysis system is able to sequentially analyse a multitude of streams and / or manually extracted samples within 1 minute. The fast presence of the measurement results and the absence of memory effects allows plant operators quick reaction not only when limits are exceeded but also in case of normalisation of values. Thus, the pure water modules of the plant are efficiently protected and no expensive high-pure water is unnecessarily drained off.

Digital Edition

PIN 25.5 Oct/Nov 2024

November 2024

Analytical Instrumentation - Picturing Viscosity – How Can a Viscometer or a Rheometer Benefit You? - Sustainable Grease Formulations: Evaluating Key Performance Parameters and Testing Method...

View all digital editions

Events

Dec 03 2024 Dusseldorf, Germany

Dec 08 2024 Anaheim, CA, USA

Turkey & Black Sea Oil and Gas

Dec 11 2024 Istanbul, Turkey

Dec 19 2024 Aurangabad, India

Jan 20 2025 San Diego, CA, USA