Measurement and testing

H2S: Can you track it before you smell it?

Sep 17 2024

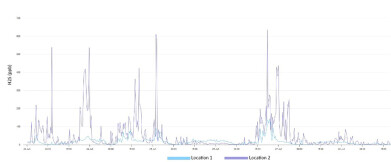

Hydrogen sulphide around and - even worse – escaping from a site can be a problem. As well as presenting a safety concern, H2S is often a nuisance odour. Detection and quantification at very low levels allows the source of the gas to be tracked down and addressed, or real-time continuous readings from around the site can demonstrate compliance with local restrictions.

H2S monitoring options

The AQMesh H2S sensor option measures the gas at single figure ppb levels, well below the level at which an odour can be detected (about 100ppb / 0.1ppm), giving ‘pre-odour’ warning or surveillance. Exceedance alerts can be set up at user-defined levels.

H2S is one of many AQMesh sensor options, including NOx, SOx and particulate matter or dust. The pods are small and, with solar power and mobile communications, can be installed very flexibly and quickly at appropriate locations. Sensor output is transmitted to the secure cloud AQMesh server, where confidential processed readings are available by secure web app login or API.

Measuring hydrogen sulphide in harsh conditions

AQMesh has been used successfully to monitor H2S across a wide range of applications and climates, including fugitive emissions along site boundaries, and projects in New Zealand, South Africa, Iceland and UK. Field testing of the sensor was initially carried out in the sludge lanes of a wastewater treatment plant, and it has since been used in oil and gas, volcanic emissions, shipping ports and biorefineries. Most recently, AQMesh has been used to monitor H2S – and other - emissions from toxic landfill sludge and wastewater spilling into a river in San Diego, USA, and a UK wastewater treatment plant is measuring H2S to protect CHP engine infrastructure.

H2S monitoring at data centres

We have seen a huge uptake from data centres, whether to comply with local regulations about back-up generator use, or to guard against the potential damage to copper circuitry from this corrosive airborne pollutant.

Fugitive hydrogen sulphide emissions

Other industrial processes where monitoring H2S in real-time can be beneficial are lime manufacture and the pulp and paper industry, where NO2, SO2, VOCs and dust can also be an issue. Some users add the AQMesh CO2 sensor to their specification as it can be used in combination with other gas measurements to be an indicator of fugitive landfill emissions.

Real-time data for landfills, oil & gas operators and industrial processors

Monitoring along the boundary of landfills, oil & gas plants or other industrial processing sites can offer real-time information to operators to ensure that staff and any nearby communities are not affected by emissions. AQMesh pods can be deployed along fencelines to monitor not only H2S but SO2, CO2, and TVOCs, including ethylene oxide, which can all be pollutants of concern. Analysis of pollutants in combination with wind speed and direction information (AQMesh offers an integrated ultrasonic wind sensor) allows pollution sources to be identified. This is particularly helpful where there are several neighbouring sites – which one could be the polluter?

All AQMesh pods are built to order with a standard lead time of 2 weeks and every user benefits from remote support for the life of the pod, wherever they are in the world.

For more information on using AQMesh air quality monitors for H2S monitoring and more, contact our experienced team today.

Digital Edition

PIN 25.5 Oct/Nov 2024

November 2024

Analytical Instrumentation - Picturing Viscosity – How Can a Viscometer or a Rheometer Benefit You? - Sustainable Grease Formulations: Evaluating Key Performance Parameters and Testing Method...

View all digital editions

Events

Jan 20 2025 San Diego, CA, USA

Jan 22 2025 Tokyo, Japan

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China