Pour point

What Are the Properties of Lubricants? - Pour Point

Mar 21 2022

Of all the properties of lubricants, pour point is one of the most important. The term is used to describe the lowest temperature at which a lubricant stops flowing under gravity and starts to solidify. It’s one of the key characteristics used to appraise flow properties and is often used to determine the quality and price of a lubricant, as well as thermal stability and overall suitability for the application.

Why pour point matters

When it comes to performance, pour point can have a big impact. When a lubricant loses its flow characteristics it also loses its ability to reduce friction between moving parts, protect against corrosion and suspend contaminants. This can not only compromise efficiency but increase the risk of unplanned downtime.

Without so much at stake, pour point is undoubtedly one of the most important properties of lubricants. It can often be the deciding factor when selecting from a group of lubricants with similar characteristics, with lower pour points generally considered more desirable as they indicate a better operating range.

Calculating pour point

Fluidity is a critical characteristic of lubricants, which is why pour point is generally calculated at 3°C above the temperature at which a liquid no longer flows at gravity. Ideally, pour point should be at least 10°C below the lowest operating temperature at which the lubricant will be used. This allows for plenty of leeway and minimises the risk of the lubricant losing its flow characteristics.

As always, standard testing methods developed by ASTM International are considered a global benchmark when calculating pour point. Specifically, the ASTM D97-17b Standard Test Method for Pour Point of Petroleum Products is used to calculate the lowest temperature at which the flow characteristics of a lubricant are compromised.

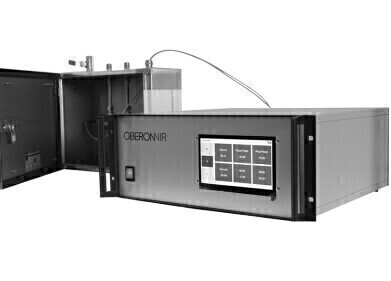

The ASTM D6892-03(2020) Standard Test Method for Pour Point of Petroleum Products (Robotic Tilt Method) is also widely used. Instead of the manual method described above, this test uses automated technology to detect movement and calculate pour point.

Improving pour point

Like other properties of lubricants, pour point can be improved with the use of additives. Usually made from polymers such as alkylated wax naphthalene and alkylated wax phenol, pour point depressants improve the flow of oil lubricants in cold temperatures. They’re especially useful for paraffinic based lubricants and can drastically improve pour point in cold operating conditions.

Want to go beyond pour point and learn more about the properties of lubricants? We cover viscosity, sulphur content, API gravity and more in ‘What Are the Chemical & Physical Properties of Lubricants.’

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 14 2025 Moscow, Russia

Apr 15 2025 Moscow, Russia

Apr 22 2025 Hammamet, Tunisia

Apr 22 2025 Kintex, South Korea

Solar & Energy Storage Summit 2025

Apr 23 2025 Denver, CO, USA

.jpg)