Fuel analysis

Mind the gap between kinematic viscosity at -20°C and the freezing point: Stabinger Viscometer™

Dec 09 2015

Current aviation fuel specifications require a low-temperature viscosity measurement and a freezing point test to determine the safe operating zone of the product. But what really happens between -20°C and the freezing point? The viscosity undoubtedly increases, but does it increase beyond the safe operation limit of the aircraft?

Viscosity

The viscosity of a fuel is closely related to pumpability over the temperature range and consistency of nozzle spray patterns. The ability of fuel to lubricate a pump may also be related to the viscosity.

For the most commonly used Jet A1 fuel the viscosity specification according to ASTM D1655 and DEF STAN 91/91 is 8 mm²/s at -20°C.

For aviation fuels containing synthesised hydrocarbons, another viscosity specification according to ASTM D7566 with maximum 12 mm²/s at -40°C was introduced recently.

Other jet fuel grades like the TS-1 and T-2 have even more stringent limits of 8 mm²/s and 6 mm²/s, respectively, at -40°C. The fuel types are mainly used in areas with extremely cold temperatures.

Most aircraft turbines are certified for a minimum cold-start temperature of -40°C at a maximum fuel viscosity of 12 mm²/s.

However, even if the specification of A1 of maximum 8 mm²/s at -20°C is fulfilled, you can be sure that at -30°C, perhaps even at higher temperatures, the viscosity exceeds 12 mm²/s.

By scanning the entire relevant temperature range it is possible to determine the exact temperature at which the critical viscosity of 12 mm²/s is determined and thereby safe operation is guaranteed.

A new specification for fluidity of jet fuel for the temperature range below -20°C is required.

Freezing Point

The minimum freezing point requirement is -47°C for Jet A1 and -40°C for Jet A.

The freezing point is particularly important and must be sufficiently low to preclude interference with flow of fuel through filter screens to the engine at the temperatures prevailing at high altitudes.

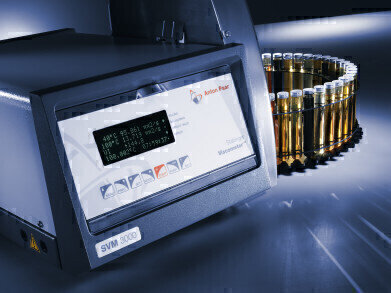

Stabinger Viscometer™

ASTM has released only one test method for jet fuel viscosity alternative to the original D445: that is D7042 'Standard Test Method for Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (and the Calculation of Kinematic Viscosity'). In interlaboratory studies guided by ASTM, Anton Paar’s Stabinger Viscometer™ has undergone the stringent testing required for aviation fuel certification for both the traditional petroleum-based jet fuels according to D1655 as well as for aviation turbine fuels containing synthesised hydrocarbons according to D7566.

Moreover, besides the standard tests the Stabinger Viscometer™ offers a new comprehensive performance test for jet fuels: a temperature scan over the entire relevant temperature range from -20°C down to -56°C, well below the freezing point requirement of aviation fuel A1. And best of all, this scan is fast: it only takes approximately the same time as a single conventional manual test at -20°C and is fully automated.

Read more about Stabinger Viscometer™: SVM™ 3000 here.

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 08 2025 Birmingham, UK

Apr 08 2025 Kielce, Poland

Apr 08 2025 Ravenna, Italy

Apr 08 2025 Southampton, UK

Apr 08 2025 London, UK