Analytical instrumentation

Strategies to Reduce Laboratory Costs While Improving Efficiency and Productivity in the Era of COVID-19 - Part 2

Nov 17 2020

In part one of this series, we demonstrated that in times of economic downturns, the natural tendency is to reduce or eliminate the level of investment in new technologies and methodologies – an obvious approach to dealing with economic uncertainty. While this is viable over the short term, the reality is that all businesses must re-evaluate their operational priorities to ensure they emerge in a better position to deal with new economic realities. For many laboratory-dependent organisations, this means looking for ways to become more efficient.

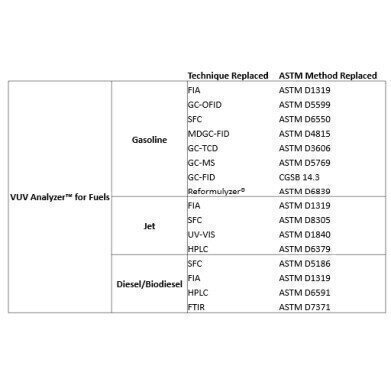

The VUV Analyzer Platform™ for Fuels can address these new realities because it is designed to analyse different fuel types with no changes in hardware or setup (Figure 1).

Table 1 highlights the traditional analytical techniques and methods used for the analysis of these different fuels. Running multiple samples on different analytical techniques is often needed. This approach requires a lot of time, and depending on the technique, significant expertise. The VUV Analyzer Platform allows you to consolidate fuels analysis to a single platform while increasing the efficiency of the analyst, meaning increased throughput with fewer analytical techniques is ultimately possible.

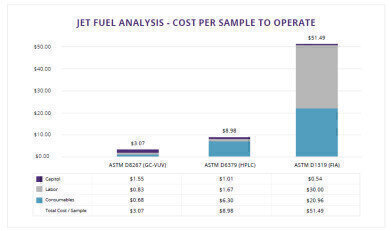

In part 1, we showed that using the VUV Analyzer Platform running D8071, cost-per-analysis could be reduced from approximately $64.63 USD per sample to $5.21 USD. For jet fuel (Figure 2) cost-per-analysis can be reduced to $3.07 USD per sample compared to FIA at $51.49 USD, and HPLC at $8.98 USD per sample. How is this possible?

The answer is not complicated and considers three variables:

Cost-of-Acquisition

- The cost to acquire the hardware usually gets the most attention as it is the upfront cost needed. Implementing the VUV Analyzer Platform does require more capital investment compared to other techniques such as FIA. However, the capital investment is only a small part of the story.

Cost-of-Maintenance and Consumables

- Consolidating multiple analytical techniques reduces the number of instruments required. This means less maintenance and consumables costs over time. There are no expensive dyes (FIA) or hazardous solvents like those used in HPLC. The VUV Analyzer Platform has one consumable - a lamp rated for 2000 hours. To put this in perspective, one user of the VUV Analyzer Platform running ASTM D8071 and D8267 has calculated that they will save approximately $125,000 USD per year (excluding labor) by replacing the other techniques.

Cost-of-Labor

- The last variable is labor. Any discussion on labor almost always revolves around reduction. However, we are referring to better utilisation of existing resources, not the elimination of that cost. The VUV Analyzer Platform eliminates the need for multiple analytical techniques, is automated and calibration free, and does not require any changes in hardware or setup when changing between fuel types. Laboratory resources can be utilized on other high-priority projects, therefore increasing productivity.

In times of economic uncertainty, capital expenditures usually get delayed or eliminated first. Laboratories looking to eliminate long-term recurring costs first are often better positioned to emerge from economic uncertainties and are better positioned for the future.

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 14 2025 Moscow, Russia

Apr 15 2025 Moscow, Russia

Apr 22 2025 Hammamet, Tunisia

Apr 22 2025 Kintex, South Korea

Solar & Energy Storage Summit 2025

Apr 23 2025 Denver, CO, USA

.jpg)