Lubricant analysis

Robust and precise inline analyser for real-time oil condition monitoring showcased at leading global condition monitoring conference

Jun 14 2023

Spectrolytic exhibited its versatile FluidInspectIR® – Inline, at the recent OilDoc exhibition in Rosenheim, Germany. Designed to revolutionise oil and lubricant monitoring, this state-of-the-art multi-sensor system offers real-time insights into oil condition, ensuring the efficient operation and protection of valuable plant assets.

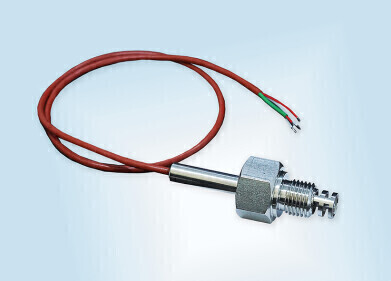

The FluidInspectIR® – Inline is a plug & play analyser that enables in-situ monitoring of oil and lubricant condition. By seamlessly integrating into the main oil circuit via a bypass system or extracting oil from a reservoir using its built-in pump, this advanced system provides continuous monitoring without disrupting operations. The inclusion of an optical particle or wear sensor further enhances its functionality, catering to a variety of monitoring needs.

One of the key advantages of the FluidInspectIR® – Inline is its user-friendly installation process, enabling remote installation and eliminating the need for complex setup procedures. Once installed, it empowers users by delivering crucial oil degradation parameters in the same format, units, and accuracy as traditional oil analysis laboratory reports. This compatibility ensures a seamless transition from laboratory-based analysis to real-time monitoring.

The FluidInspectIR® – Inline is specifically designed for a wide range of industries and applications. It is the perfect choice for monitoring and safeguarding valuable plant assets in power generation, including engines, turbines, and transformers. Additionally, it offers significant benefits to metal-working plants, such as steel and aluminium, as well as hydraulic, gear, and other rotating equipment.

With 24/7 monitoring capabilities, the FluidInspectIR® – Inline provides users with real-time data on key oil parameters crucial to assessing degradation, contamination, additive depletion, and physical properties. Parameters such as oxidation, nitration, sulphation, water content, soot levels, glycol presence, and various physical parameters including TAN, TBN, ipH, and Vis100/40, are presented in the same format and accuracy as standard oil analysis laboratory reports. Moreover, the system can be further customised by integrating one or two serial modules, enabling the addition of optical particle analysis, wear sensors, viscometers, conductivity probes, or any other sensor as per user requirements.

Data acquisition is simplified with the FluidInspectIR® – Inline, as it seamlessly transmits the collected data to Spectrolytic's cloud. Users can access and download the data via a user-friendly dashboard. The system also offers support for various cloud platforms, including Azure and AWS, through MQTT or Web API protocols. Furthermore, direct integration with on-site controller systems is available, ensuring seamless compatibility with existing infrastructure.

The FluidInspectIR® – Inline brings significant benefits to end users. By leveraging its real-time monitoring capabilities, organisations can reduce unplanned downtime, optimise oil drain intervals with confidence, mitigate health and safety hazards, implement data-driven maintenance strategies, minimise their CO2 footprint, and gain support for warranty claims.

Digital Edition

PIN 25.5 Oct/Nov 2024

November 2024

Analytical Instrumentation - Picturing Viscosity – How Can a Viscometer or a Rheometer Benefit You? - Sustainable Grease Formulations: Evaluating Key Performance Parameters and Testing Method...

View all digital editions

Events

Jan 20 2025 San Diego, CA, USA

Jan 22 2025 Tokyo, Japan

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China