Lubricant analysis

Innovative moisture-in-oil Sensor is the ideal choice for industrial lubricant monitoring

Oct 10 2023

Ensuring the safe and reliable operation of gears, transformers, and industrial facilities over extended periods is key to a multitude of industrial processes. The integration of precise sensor technology for the continuous monitoring of lubricants condition plays a vital role to achieving smooth process operations.

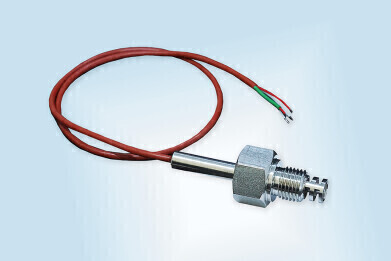

To cater to this demand, IST AG have recently introduced a highly advanced moisture-in-oil sensor, featuring a compact, digital humidity and temperature module (RH/T). This sensor provides continuous monitoring and measurement of the relative degree of saturation of water content in oils and fuels, represented as %RH (water activity aw in %). This sensor will indicate the current state and performance of the oil, as opposed to other devices on the market which measure absolute water content in ppm H2O.

Over time, lubricants will age because of degradation, additive breakdown, and impurities. As lubricants age, their capacity to absorb water changes, leading to diminished performance and, as a result, potentially causing machine downtime and costly repairs. Preventive maintenance plans now place far more emphasis on the continuous monitoring of a lubricant's water absorption capacity.

For efficient industrial operations, moisture-in-oil monitoring is crucial in applications where scheduled maintenance and machine downtime are critical, such as ship engines and their gearboxes, commercial vehicles, train transformers, and power engineering in wind turbines and their generators. Precise and reliable moisture monitoring is also vital in industrial facilities with large-volume oil reservoirs, such as drilling and paper machines, and smaller systems like mobile oil filtration units.

Key features of this highly advanced sensor include an operating range of 0 to 100 % RH and a temperature range of -40 to 120°C. It offers superb reproducibility (+/- 0.2 %RH; +/- 0.1°C) and accuracy (+/- 3% RH; +/- 0.2°C). Housed in a robust and compact 1.4571 stainless steel casing with an M14 x 1.5 mm thread, this sensor is the perfect choice for demanding industrial environments. Its universal digital electronic interface (I2C) enables seamless integration into a variety of measurement and monitoring systems. End users have the sensor delivered temperature compensated and calibrated, and an evaluation test board with analogue (0-10V) outputs is also available.

Customer service is a keystone principle at IST AG, so the company offers application-specific assembly and calibration solutions to manufacturers of measuring instruments, to ensure that this cutting-edge moisture-in-oil sensor meets the specific criteria of a plethora of industrial applications.

Digital Edition

PIN 25.6 Buyers' Guide

January 2025

Buyers' Guide Directory - Product Listings by Category - Suppliers Listings (A-Z) Articles Analytical Instrumentation - ASTM D7042: The Quantum Leap in Viscosity Testing Technology -...

View all digital editions

Events

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China

Trinidad and Tobago Energy Conference 2025

Feb 10 2025 Point Lisas, Trinidad

Feb 11 2025 Lagos, Nigeria

Feb 13 2025 Manama, Bahrain