Oil analysis

What is Oil Condition Monitoring?

May 29 2021

From powering engines to lubricating moving parts, oil is fundamental to the manufacturing and transport sectors. Quality can have a major impact on both productivity and profitability, making Oil Condition Monitoring (OCM) a top priority for most consumers. Also known as Used Oil Analysis (UOA), the process involves monitoring the quality and characteristics of oil to maintain efficiency and detect any issues that could compromise performance.

The history of OCM

The early days of OCM can be traced back to 1946, when US railroad engineers started to detect component deterioration by analysing diesel engine lubricant. Samples were collected and sent to laboratories where spectrographs were used to detect chemical elements such as copper and iron. The results were then used to identify the early warning signs of engine failure and carry out repairs before a total breakdown occurred.

Oil Condition Monitoring and predictive maintenance

Today, Oil Condition Monitoring is fundamental to any predictive maintenance strategy. Designed to monitor the performance of equipment and schedule repairs before failure, predictive maintenance minimises the risk of breakdown and helps protect valuable assets. The value of OCM spans across a wide range of sectors, helping to lubricate the moving parts used to power wind turbines, keep conveyer belts running smoothly at food production plants, prevent premature wear of heavy duty mining machinery, and more.

“Operational issues in machines, engines and other components are often reflected in the condition of the lubricant oil being used,” asserts Intertek, a British-based company that’s been providing gold-standard quality assurance, inspection, testing and certification solutions for more than 130 years. “Regularly scheduled oil condition monitoring or used oil analysis can identify mechanical problems before they impact the efficient running of machinery, avoiding costly headaches later on.”

Techniques used to carry out OCM

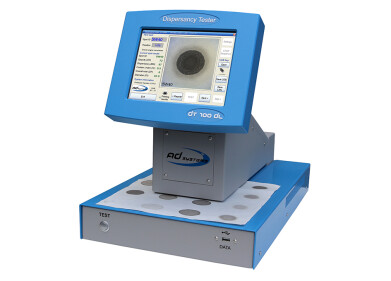

Scientists rely on a variety of techniques to carry out Oil Condition Monitoring, each with its own unique pros and cons. Titration is one of the most common methods used to measure key oil parameters. Near-infrared spectroscopy is coveted for its speed and accuracy, with the capacity to deliver results for multiple chemical and physical parameters in under 60 seconds. Voltammetry is widely used to detect antioxidant additives, with a new technique known as Linear Sweep Voltammetry (​LSV) recently gaining traction.

Want to know more about how to maximise oil condition monitoring efficiency and make well-informed decisions on which methods to use? On June 03, key speakers Dave van Staveren, Christian Haider and Uwe Loyall will explore best-practice methods in the online session, ‘How to maximize efficiency of your oil condition monitoring.’

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 08 2025 Birmingham, UK

Apr 08 2025 Kielce, Poland

Apr 08 2025 Ravenna, Italy

Apr 08 2025 Southampton, UK

Apr 08 2025 London, UK

.jpg)