Lubricant analysis

Elemental analysis of heavy (residual) fuel oils by XRF

Dec 15 2010

The broad term “heavy fuel oil” refers to the highest boiling point distillate fractions and non-boiling residuum of refined crude oils, used as fuel for industrial heaters, boilers and engines used for instance in tankers (Fig. 3).

Natural contaminants found in crude oil such as sulfur, vanadium, nickel and iron are largely tied up in complex non-volatile asphaltene and porphyrin molecules. These elemental contaminants thus remain and concentrate in the heaviest distillate fractions associated with heavy fuels; refining process contaminants also concentrate in these streams. In a high temperature, oxygen rich combustion engine environment, the concentration and interaction of these variously abrasive and corrosive elemental contaminants can become virulent and highly damaging, reducing equipment service life up to 80 %.

Standard test methods

The ISO 8217 marine fuel standard specifically references wavelength dispersive X-ray fluorescence (WDXRF) as a preferred analysis method for sulfur, vanadium and nickel analysis per ISO test methods 14596 and 14597. This technique provides well-known advantages in overall speed of analysis owing to ease of sample prep (no dilution required) and excellent precision and stability from ppm to percentage concentrations across multiple elements. In addition, the British Institute of Petroleum (IP) proposed a new industry test standard in 2009 specifically for WDXRF analysis of residual fuel oil covering ten elements of interest mentioned above.

Instrumentation

The ARL OPTIM’X (Fig. 1) is a cost effective WDXRF instrument designed for ease of use, rapid deployment, and minimal lifetime operational costs. The resulting analytical sensitivity for even ultra-low contaminant concentrations rivals that of higher-powered and more expensive WDXRF instruments, while also providing full capabilities at high concentrations, e.g., 4.5 % sulfur.

Despite occupying the low end of the distillate fuel spectrum, heavy residual fuels must adhere to tight quality restrictions to ensure proper marine engine performance. The low ppm levels of contaminants tolerated require analysis with excellent sensitivity, yet also analytical flexibility to measure percentage element concentrations. The ARL OPTIM’X exceeds the requirements of ISO 8217 and other international standards for sensitivity, range and reliability of heavy fuels analysis. Its unique design includes optional enhanced performance on selected elements through configuration of two MultiChromator™ fixed channels, in which specially curved and focused crystals further improve sensitivity or reduce analysis time.

Analytical sensitivity

With its SmartGonio configuration, the ARL OPTIM’X provides extremely low limits of detection for virtually all contaminant elements in heavy fuels and well within the quality limits set by ISO 8217. For the more difficult lighter elements, an additional fixed channel configuration provides further sensitivity of 2,102 ppm and standard deviation of 9.5 ppm or 0.44 %, the instrument provides reproducible results over time without need for recalibration.

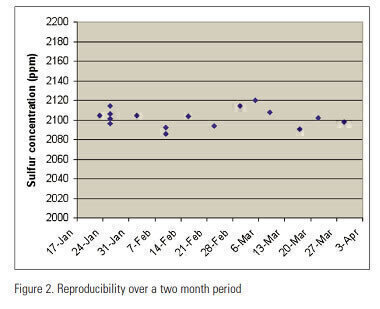

Reproducibility

The design of the ARL OPTIM’X also provides extremely stable analytical results over time, without need for recalibration. Reproducibility over a two month period on the same medium-range sulfur sample of 2.1 % (2,100 ppm) is shown in Figure 2.

Conclusion

The ARL OPTIM’X is a uniquely designed cost effective WDXRF instrument that exceeds the requirements of ISO 8217 and other international standards for sensitivity, range and reliability of heavy fuels analysis.

More on www.thermoscientific.com/optisulfur

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 08 2025 Birmingham, UK

Apr 08 2025 Kielce, Poland

Apr 08 2025 Ravenna, Italy

Apr 08 2025 Southampton, UK

Apr 08 2025 London, UK