Lubricant analysis

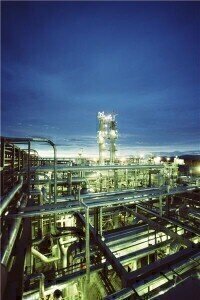

Rafinerija Nafte Brod Selects Technology to Improve Quality of Refined Lubricants and Fuels

Nov 09 2012

UOP LLC, a Honeywell (USA) company, and ExxonMobil Research and Engineering Company (EMRE) announced recently that Rafinerija Nafte Brod, Bosnia and Herzegovina’s sole oil refinery, has selected UOP and EMRE technology to improve the quality of refined lubricants and fuels.

The licensing agreement is the first under a joint licensing alliance formed by Honeywell’s UOP and EMRE last year.

The new technology will allow Rafinerija Nafte Brod to improve its product quality and environmental performance. The refiner will combine Honeywell’s UOP Unicracking hydroprocessing solutions with EMRE’s distillate and lubricant de-waxing technologies to produce ultra-clean jet and diesel fuels and high-quality lubricant base stocks.

Pete Piotrowski, vice president and general manager of Process Technology and Equipment for Honeywell’s UOP said, “The new Unicracking complex will help the refinery increase their fuel and lube yields through an integrated and cost-effective approach.”

“The EMRE technology platform provides a one-stop solution for Rafinerija Nafte Brod’s hydroprocessing and fuel de-waxing needs,” said Vince Alberico, manager of Technology, Sales and Licensing for EMRE.

The Unicracking complex will include Honeywell’s UOP two-stage Unicracking process integrated with EMRE’s MSDW process for selective dewaxing lubricant feedstocks and EMRE’s MIDW processes for dewaxing diesel feedstocks. The complex will upgrade more than 45,000 barrels per stream day of kerosene, diesel and vacuum gas oil feedstock into high-quality diesel and jet fuels. It will also produce high-quality base oils that will be used for the production of Group II and Group III lubricants at Refineria Ulia Modricha, which is part of the oil refining production chain in Bosnia and Herzegovina. The new complex is scheduled to start operations in 2016.

Honeywell’s UOP Unicracking technology provides flexibility to upgrade a variety of feedstocks to high-quality, lighter transportation fuel products. It can also be used to produce low-sulphur naphthas for reforming into gasoline, or to upgrade FCC products for additional distillate production or sulphur removal.

EMRE’s MSDW and MIDW processes are advanced proprietary technologies to optimise production of lubricants and distillate fuels. The MSDW process is designed to overcome high-sulphur environments and provides the highest yields and viscosity available in the industry. MIDW is a selective catalytic dewaxing process that can improve yields of high-quality diesel with excellent cold flow properties.

Honeywell’s UOP has been developing and licensing hydroprocessing solutions, including advanced catalysts and specialty equipment, for nearly 100 years. As a major research and engineering organisation, EMRE develops a broad spectrum of refining technologies to safely and reliably respond to an array of process challenges.

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 08 2025 Birmingham, UK

Apr 08 2025 Kielce, Poland

Apr 08 2025 Ravenna, Italy

Apr 08 2025 Southampton, UK

Apr 08 2025 London, UK