Lubricant analysis

What Are the Properties of Lubricants? - Hydrolytic Stability

Mar 16 2022

On par with metallic particles, water is one of the most damaging contaminants faced by lubricants. As well as accelerating issues such as rust and corrosion, water contamination can permanently degrade the quality of a lubricant and reduce its load-carrying capacity. With so much at stake, lubricants with the ability to resist degradation in the face of water contamination are coveted by operators. This trait is called hydrolytic stability and is one of the most important properties used to asses the quality, suitability and performance expectations of lubricants.

Understanding hygroscopicity

Most oils are naturally hygroscopic, which means they actively absorb airborne moisture. This process is known as hygroscopicity and can fast-track water contamination. As well as moisture from the surrounding environment, lubricants can absorb H2O from external sources, such as spills and leaks. After a lubricant is contaminated with H2O, hydrolytic stability becomes a major concern for operators.

ASTM D2619-09

The ASTM D2619-09 - Standard Test Method for Hydrolytic Stability of Hydraulic Fluids, or the Coke bottle test as it’s commonly known in the industry, is one of the most widely used methods to test for hydrolytic stability. The method uses predetermined conditions to differentiate the relative stability of lubricants and other fluids when exposed to H2O.

Hydrolytic stability and temperature

While hydrolytic stability is usually determined under controlled test conditions, it’s important to factor in variables. Temperature is one of the most important factors that can affect hydrolytic stability, with both increases and decreases potentially compromising how well a lubricant can withstand degradation caused by water exposure.

Why hydraulic stability matters

Hydraulic stability is a major property of concern for mechanical operators as it has a direct impact on hydrolysis, chemical reactions that occur when water molecules break down chemical bonds. In lubricants, hydrolysis can cause a range of physical and chemical issues. Over time, the process can reduce the viscosity of a lubricant. This can reduce load-carrying capacity, accelerate wear and increase particulate contamination. Hydrolysis can also affect the chemical characteristics of lubricants and lead to the formation of acids. This includes carboxylic acids which can cause major damage to machines and moving parts.

Monitoring water contamination

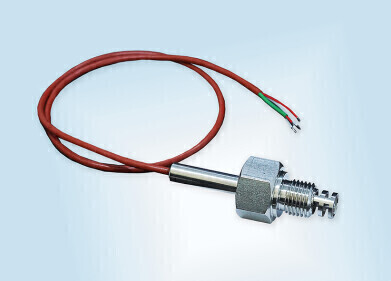

A variety of methods are used to monitor water contamination in lubricating oils, including Fourier transform infrared (FTIR) spectroscopy scans used to detect carboxylic acids, a tell-tale sign of hydrolysis. Handheld stainless steel immersion probes are also gaining popularity and allow operators to measure moisture concentrations in a matter of seconds.

A holistic approach to lubricant analysis

Hydraulic stability is just one of many properties assessed when assessing the quality of lubricants and determining suitability for different applications. For more information on the properties of lubricants viscosity, as well as other key characteristics such as thermal stability and pour point, don’t miss ‘What Are the Chemical & Physical Properties of Lubricants?’

Digital Edition

PIN 25.5 Oct/Nov 2024

November 2024

Analytical Instrumentation - Picturing Viscosity – How Can a Viscometer or a Rheometer Benefit You? - Sustainable Grease Formulations: Evaluating Key Performance Parameters and Testing Method...

View all digital editions

Events

Jan 20 2025 San Diego, CA, USA

Jan 22 2025 Tokyo, Japan

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China