-

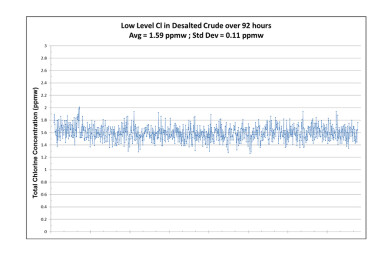

A closed loop sample of 1.59 ppmw was run through the analyzer for over 92 hours resulting in a standard deviation of 0.11 ppmw.

A closed loop sample of 1.59 ppmw was run through the analyzer for over 92 hours resulting in a standard deviation of 0.11 ppmw. -

Analytical instrumentation

Real-time total chlorine monitoring to ensure operational reliability and product quality

Jan 22 2025

Corrosion at petroleum refineries is a critical problem worldwide. In the United States alone, corrosion causes $3.7 billion in direct costs annually from maintenance, vessel expenditures, and fouling. This colossal figure is in addition to the estimated loss of as much as $12 billion in profits due to decreased capacity, unit outages, and premature turnarounds.

Chlorine in crude oil can hydrolyse during processing to form hydrochloric acid. The crude oil desalter is the first line of defence in preventing corrosion, but an effective chloride monitoring solution must be implemented to provide a proper defence. Many refiners rely on semi-periodic testing of inorganic chlorides to get the job done. However, what if a desalter upset occurs in between testing periods? Worse yet, what if an organic chlorine slug is present in the incoming crude? The desalter will remove only the extractable inorganic chlorides, not organic chlorides, and any chlorides that pass through the desalter have the potential to cause fouling and corrosion issues. Refiners who don’t rely on semi-periodic testing typically only monitor inorganic chlorine. While this is very important for desalter efficiency, it does not capture all threats.

Online chlorine analysis in crude oil presents more challenges due to low-level quantification requirements and sampling complications. To meet these needs, XOS has developed a MWDXRF online chlorine analyser. Clora Online uses MWD XRF technology and delivers real-time, continuous analysis of total chlorine with an LOD of 0.2 ppmw in hydrocarbons and 0.6 ppmw in aqueous process streams. Results are delivered every 15-300 seconds, depending on user preference. Clora Online offers an extended range up to 3000 ppmw, allowing for the detection of a chloride spike, which may indicate an upset in the desalting process or the presence of an organic slug. This enables refiners to act quickly and avoid potential hazards.

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Apr 14 2025 Moscow, Russia

Apr 15 2025 Moscow, Russia

Apr 22 2025 Hammamet, Tunisia

Apr 22 2025 Kintex, South Korea

Solar & Energy Storage Summit 2025

Apr 23 2025 Denver, CO, USA

.jpg)