-

Table 2: RSD repeatability values for the ARL ADVANT’X on copper, mercury and sulfur determination in FCC catalysts.

Table 2: RSD repeatability values for the ARL ADVANT’X on copper, mercury and sulfur determination in FCC catalysts. -

Analytical instrumentation

Fluid Catalytic Cracking (FCC) catalyst analysis using Thermo Scientific X-ray fluorescence spectrometers

Nov 17 2010

The petrochemical industry relies heavily on FCC catalysts for the production of a variety of organic intermediate building blocks. Usually, this type of material is doped with precious metals such as platinum or palladium. The precious metal concentrations are often directly related to catalyst performance. Poisoning of the catalysts by common petroleum contaminants such as copper is a concern when optimizing the conversion process. Hence, monitoring the composition of FCC catalysts allows higher conversion yields in petrochemical refineries.

XRF offers particular advantages when analyzing FCC catalysts. It is the only technique capable of analyzing solids without laborious sample preparation. Other techniques often require a lengthy chemical digestion before actual analysis. XRF also offers multi-element analysis capability combined with a wide dynamic ranging from ppm up to % levels. For these reasons XRF is also adopted as preferred technique to analyze FCC catalysts by international bodies such as ASTM (e.g. ASTM D7085). The remainder of this article describes the use of Energy Dispersive XRF and Wavelength Dispersive-XRF for the analysis of catalysts.

Catalyst screening with the Thermo Scientific ARL QUANT’X EDXRF analyzer

The ARL QUANT’X EDXRF analyzer is used to determine platinum (Pt) and chlorine (Cl) content of aluminosilicate catalysts. The 50 Watt QUANT’X is equipped with a 3 mm thick Si(Li) detector. The sensitivity of this detector allows sub ppm detection limits for heavy elements such as platinum and other precious metals. Catalyst powders are measured as received by transferring 4 g of powder into an XRF cup sealed with a 4 µm thick polypropylene film on one side and a mesoporous film on the other side. The mesoporous film allows analysis in vacuum avoiding the use of helium which would add extra cost. Total analysis time equals 100 s. Table 1 shows the repeatability values for this application.

Table 1: RSD repeatability values on Pt and Cl in FCC catalysts.

Analysis of FCC catalysts using the Thermo Scientific ARL ADVANT’X WDXRF spectrometer

The 2500 Watt ARL ADVANT’X sequential WDXRF instrument allows excellent sensitivity and repeatability. In this application it is used to analyze typical catalyst contaminants like sulfur (S), copper (Cu) and mercury (Hg). Sample preparation is kept to a minimum by analyzing the loose powders directly. The total time of analysis is less than 100 s. A Ge111 crystal in combination with an FPC detector is used to determine S while a LiF200 crystal and SC detector is used to determine Cu and Hg. Figure 1 shows the calibration curve for S, indicating an accuracy of around 100 ppm for a concentration range from 0 to 1.6% m/m.

Figure 1: Calibration curve for sulfur in dicating a standard error of estimate of 0.011% m/m.

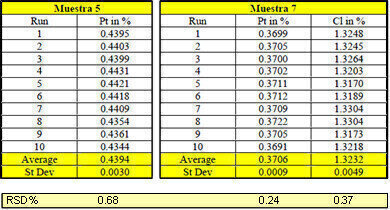

Table 2 gives an overview of the repeatability attainable with an ARL ADVANT’X on loose powders. A relatively short but effective sample preparation consisting of pressing the powder into a pellet would further improve repeatability.

Table 2: RSD repeatability values for the ARL ADVANT’X on copper, mercury and sulfur determination in FCC catalysts.

Conclusions

Either by using EDXRF or WDXRF the examples of this article shows that XRF distinguishes itself as a fast tool for a variety of FCC catalyst analyses. While EDXRF is more suitable to screen catalyst composition, WDXRF is the preferred technique when high throughput and repeatability are required.

To see our complete product portfolio, please visit www.thermoscientific.com/xpetro

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

SPE International Conference on Oilfield Chemistry

Apr 09 2025 Galveston, TX, USA

Apr 14 2025 Moscow, Russia

Apr 15 2025 Moscow, Russia

Apr 22 2025 Hammamet, Tunisia

Apr 22 2025 Kintex, South Korea