Analytical instrumentation

Rugged Probes and Flow Cells Meet Refinery Requirements

Feb 19 2020

With the adoption of the Industry 4.0 initiative, collecting useful data and transforming it into actionable information is a critical requirement. In para-xylene and petrol/gasoline plants, good data collection starts with the proper sample interface connected to a process analyser. For refineries where the sample is very clean (free from particulates and moisture), a direct in-situ single-sided transmission (SST) probe is the best choice. It allows direct process measurement with simple installation in a pressurised line or reaction vessel.

Caption Figure 2 The SST Probe with a welded flange is installed into the side of a pressurised reaction vessel.

Easily installed in a pipe or reactor through a single access port, the SST probe is compatible with most fiber optic-based process analysers. The corrosion-resistant SST is rugged and has a vibration resistant design that can easily withstand repeated temperature and pressure cycling.

For faster maintenance and cleaning of insertion probes, Guided Wave’s Extractor Mechanism can be used. The controlled extraction of an in-line probe from pressurised process streams or reactors can be accomplished without shutting down the process. The extractor allows the process to continue during routine probe maintenance. Coupled with a gate or ball valve, these extractors have proven safe and effective in a variety of reï¬nery installations such as Reformer, Gasoline Blending, Blender and Feed Streams, all saving downtime. James Low, Guided Wave’s Director of Sales and Support states, “The SST insertion probe extractor assembly is worth every penny when you consider the time saved on insertion probe maintenance.” He continues, “I’ve been with Guided Wave almost since its beginning and the SST probe and the multipurpose flow cell are extremely durable and reliable. Our probes and flow cells are compatible with nearly every brand of an analyser and in normal reï¬nery use they function virtually forever”.

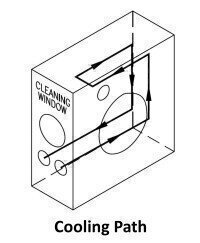

Caption Figure 3 The path of the heat exchange fluid is shown in the above image.

However, for diesel/gas oil applications it is highly recommended to use a heated Multipurpose flow cell (MPFC). By maintaining the temperature of the sample interface, trace levels of water in the sample are dissolved, which in turn improves the quality of the measurements. While direct insertion probes eliminate sample loops and sample systems and their associated problems, sometimes it is necessary to install sample loops for safety, service, and/or sample conditioning reasons. The MPFC is a convenient, compact, rugged sample interface that is easy to install and even easier to service. The cell’s sapphire windows can be cleaned by simply removing a clean-out plug for direct access to the windows without disconnecting process lines or ï¬ber optic cables. The clean-out plug on the MPFC is a design innovation by Guided Wave. A certified version of the MPFC is available that is rated to 1000 psi with temperatures up to 300°C depending on the o-ring material.

Guided Wave probes and flow cells offer high throughput, collimated optical beams through the sample, yielding lower noise and more accurate transmission values free of sample index of refraction effects. Contact Guided Wave for product selection guides.

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Mar 17 2025 Houston, TX, USA

Mar 18 2025 Beijing, China

Mar 19 2025 Manila, Philippines

Mar 20 2025 Brussels, Belgium

Mar 20 2025 Guangzhou, China

.jpg)

.jpg)