Analytical instrumentation

Rugged Probes and Flow Cells for Accurate FT-NIR Performance and Measurements

Sep 15 2020

For many refinery applications, online process measurements using FT-NIR or UV-VIS spectroscopic process analysers will provide immediate, accurate, reliable 24/7 data for critical decision making and profitable production. Regardless of the brand of the FT-NIR analyser, if the sample interface; the flow cell, or the insertion probe is substandard, so will the accuracy of the measurements.

As the industry leader for insertion probes and flow cells for FT-NIR analysers Guided Wave offers 10-12-week lead times on most flow cells and insertion probe. Designed to withstand high temperatures and pressures this CRN rated FT-NIR insertion probes provide 10-15% better optical efficiencies than other brands.

Flow Cells are Compatible with Any FT-NIR Vendor

Both the standard Multipurpose Flow Cell and the Heated Flow Cell are manufactured by Guided Wave to facilitate full integration with any fiber-optic spectrometer manufacturer. The Heated Flow Cell is fully compatible with the Matrix-F FT-NIR analyser, ABB’s full line of FT-NIR spectrometers, Metrohm’s NIRS XDS Process Analyzer, and AIT’s optical analysers. The market-leading optical efficiency of Guided Wave’s sample interfaces will improve the optical performance of any spectrometer when connected with 400 to 600-micron fiber optical cables and SMA 905 or FC connectors.

The High Safety Flow Cell for FT-NIR

Thanks to the dual seals and a sniffer port, refineries dealing with hazardous or corrosive samples can improve operations safety with the High Safety Flow Cell. Constructed out of Hastelloy C276 with Kalrez seals, the High Safety Flow Cell is rated for 250C typical operation at 300psi. The safety sniffer port provided between o-ring seals, allows for a connection to a leak detection system to be used as an indicator of primary seal failure.

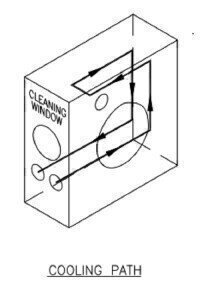

Field Serviceable Flow Cells for FT-NIR Analysers

Every FT-NIR flow cell can be serviced in the field by refinery personnel. During the field service the o-rings and other nonmetallic components can be cleaned and if needed replaced. Alternatively, the flow cell can be sent back to the factory for service repair.

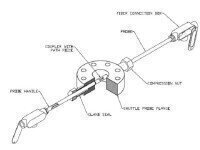

The Shuttle Probe for High-Temperature Inline Processes

The Shuttle Probe is an inline flanged probe designed for high-temperature applications. Installed directly into a 4-inch or larger process pipe, the design protects the optics from the excessive process temperature that would otherwise damage other probes. Additionally, cleaning of the optical windows and subsequent probe referencing are possible without having to interrupt the process. The shuttle probe was designed to enable 24/7 operation of the process even during probe maintenance.

Industry-Proven for Over Three Decades

The best FT-NIR process spectrometer performance requires sample interfaces that are not overly sensitive to vibration, temperature, and pressure changes. Choose Guided Wave’s probes and flow cells for over 35 years of industry-proven success.

For more information please click here.

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Mar 17 2025 Houston, TX, USA

Mar 18 2025 Beijing, China

Mar 19 2025 Manila, Philippines

Mar 20 2025 Brussels, Belgium

Mar 20 2025 Guangzhou, China

.jpg)

.jpg)