Sulphur analysis

Cartesian Geometry EDXRF: More Analytical Capabilities at an Affordable Price

Jun 20 2023

Elemental analysers are essential tools for the petroleum industry. Whether monitoring crude oil, optimising the refining process, or improving the quality of products — elemental analysis is critical. It is used for processing purposes, meeting contract agreements, and complying with regulatory requirements worldwide. That is why accurate and reliable, versatile analysers are needed to address a wide range of needs for refineries, contract labs, etc., while still suiting budgets and occupying a small amount of space in the lab or testing facility.

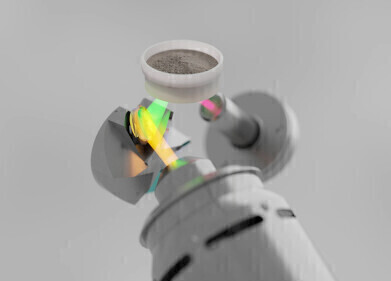

Featuring Cartesian Geometry EDXRF, NEX CG II is Rigaku’s all-in-one petroleum analyser. It offers fast, reliable measuring and monitoring for ultra-low sulphur applications, chlorine and metals, and much more. NEX CG II provides rapid, non-destructive qualitative and quantitative elemental analyses of sodium to uranium in almost any matrix and is ideal for measuring ultra-low and trace element concentrations up to percent levels.

The unique close-coupled Cartesian Geometry (CG) optical kernel employed by NEX CG II delivers enhanced elemental analysis and gives superior analytical power to its users. It excels in complex applications with trace elements and variable base matrices, serves many screening and monitoring needs, and offers users a multipurpose system for meeting multiple testing methods and standards.

Cartesian Geometry EDXRF Offers an Unmatched Price/Performance Ratio

Elemental analysis by EDXRF (energy dispersive X-ray fluorescence) is one of the most cost-effective techniques for determining elemental composition — systems are typically more affordable than other technologies, are easy to use, and require minimal or no sample preparation. What makes NEX CG II an excellent option is its 3D Cartesian Geometry X-ray optics. This configuration dramatically increases the signal-to-noise ratio and delivers the highest sensitivity to users. NEX CG II rivals large, more expensive systems and replaces the need for multiple single-element benchtops. This unmatched performance and smaller footprint make it an attractive instrument for any commercial lab or R&D facility. It is powerful enough for experts and easy to use for those running routine quality control.

Multi-application Versatility for ASTM, EPA, and International Compliance

NEX CG II offers users exceptional versatility to meet international regulations and testing requirements for measuring sulphur in petroleum oils, fuels, and ultra-low sulphur in diesel (ULSD).

- Analysis of ultra-low sulphur diesel (ULSD) per ASTM D7220

- Analysis of ultra-low sulphur in gasoline per U.S. EPA Tier 3 Standards

- Analysis of sulphur in automotive fuels per ISO 13032, IP 532, and EN ISO 20847

- Analysis of sulphur in petroleum products per ASTM D4294 and EN ISO 8754

Additionally, NEX CG II allows users to analyse more than sulphur. It gives users more analytical capabilities to measure lead and manganese and delivers the lowest chlorine detection limits for ASTM D4929 compliance using Part C methodology.

- Analysis of ultra-low chlorine in crude oil per ASTM D4929 Part C

- Analysis of lead in gasoline per ASTM D5059 Part C and A

- Analysis of manganese in gasoline per ASTM D5059 Part D

- Analysis of metals in crudes and residual fuels per ASTM D8252

Digital Edition

PIN 25.5 Oct/Nov 2024

November 2024

Analytical Instrumentation - Picturing Viscosity – How Can a Viscometer or a Rheometer Benefit You? - Sustainable Grease Formulations: Evaluating Key Performance Parameters and Testing Method...

View all digital editions

Events

Jan 20 2025 San Diego, CA, USA

Jan 22 2025 Tokyo, Japan

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China