Safety

New Solutions for Optimising Plant Operations with the Industry’s First Online Simulator

Feb 05 2014

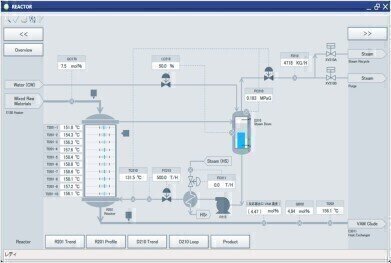

Yokogawa (Netherlands) Electric Corporation announces that in April it will begin offering new solutions for optimising plant operations in the oil & gas, petrochemical, and other industries. These solutions will be provided as part of Yokogawa’s VigilantPlant Services suite to support safe, stable, and highly efficient plant operations. The technology underlying these solutions is Yokogawa’s newly developed MIRROR PLANT online simulator.

The MIRROR PLANT simulator can visualise the internal state of a plant process and make near-term predictions on plant behaviour. An industry first, this simulator operates in synchronisation with the plant control system and features the good performance required in commercial plants. By means of high-speed calculations, the simulator can make near-term predictions on the state of a plant. Operators can then anticipate events and take action earlier to ensure safe operation.

Yokogawa and its subsidiary, Omega Simulation Co., Ltd., jointly developed the MIRROR PLANT online plant simulator. It operates in synchronisation with the plant control system and constantly updates a process model. Based on this simulator, Yokogawa will offer support solutions that help its customers optimise their plant operations.

The MIRROR PLANT simulator operates in synchronisation with the plant control system. Based on real-time manufacturing process information and using a proprietary function for adjusting model parameters, MIRROR PLANT precisely simulates the state of a plant. By using plant models, MIRROR PLANT visualises the current state of the plant, the state of the plant up to several hours in the future, and the state at plant locations where it is not possible to measure temperature or pressure. It then displays these results on screen at a CENTUM VP integrated production control system operator terminal or at a standard PC. MIRROR PLANT also has an alarm function that can alert operators to potential problems. As such, the MIRROR PLANT solution can help Yokogawa’s customers operate their plants safely and efficiently while maintaining product quality.

A field test of MIRROR PLANT was conducted from 2011 to 2013 at a plant of Mitsui Chemicals, Inc., and the results showed that it efficiently stabilised and optimised the operation of a distillation tower. As a result, MIRROR PLANT won the Technology Award from the Society of Instrument and Control Engineers (SICE), which commended this innovative technology for boosting plant productivity and safety.

Digital Edition

PIN 25.5 Oct/Nov 2024

November 2024

Analytical Instrumentation - Picturing Viscosity – How Can a Viscometer or a Rheometer Benefit You? - Sustainable Grease Formulations: Evaluating Key Performance Parameters and Testing Method...

View all digital editions

Events

Nov 26 2024 Paris, France

Nov 26 2024 Amsterdam, Netherlands

Nov 27 2024 Istanbul, Turkey

Biogas Convention & Trade Fair 2024

Nov 27 2024 Hanover, Germany

Dec 03 2024 Dusseldorf, Germany