-

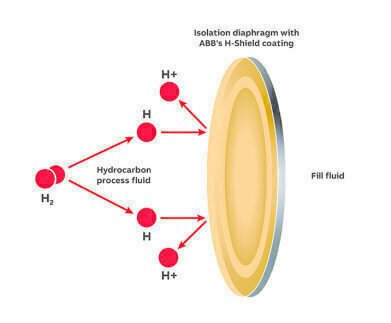

This image shows the H-shield coating on the diaphragm of a pressure transmitter

This image shows the H-shield coating on the diaphragm of a pressure transmitter -

-

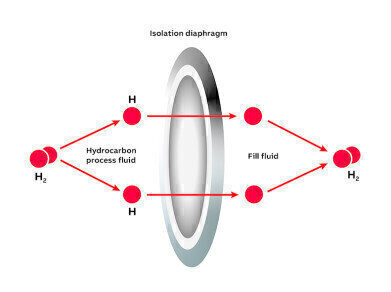

This image shows Hydrogen ions small enough to penetrate the diaphragm on the transmitter

This image shows Hydrogen ions small enough to penetrate the diaphragm on the transmitter -

This image shows Hydrogen unable to penetrate the nano-coating provided by H-shield

This image shows Hydrogen unable to penetrate the nano-coating provided by H-shield

Measurement and testing

Nano-coating tackles the issue of hydrogen permeation in pressure transmitters

Aug 15 2022

The oil and gas sectors rely heavily on pressure transmitters to maintain safe and efficient operations at industrial plants such as refineries and petrochemical plants. However, these transmitters often fail due to hydrogen permeation, which often goes undiagnosed. ABB have developed a new coating to deal with this problem economically and efficiently.

Hydrogen permeation occurs when conditions cause the molecule to split into two hydrogen ions, which are therefore small enough to pass through the molecular structure of the transmitter’s diaphragm. Having passed the diaphragm, the ions re-unite to create a larger hydrogen molecule that is too large to return through the diaphragm. The hydrogen then accumulates as it is trapped and diffuses into the transmitter’s fill fluid, affecting its performance. As time goes by the build-up of hydrogen will create a bulge in the diaphragm, which only becomes apparent on removing the transmitter.

Processes that involve high pressures of over 1,000 psi/68.95 bar or high temperatures exceeding 176°C/350°F are more likely to struggle with hydrogen permeation in pressure transmitters. These higher energy conditions increase the likelihood of hydrogen molecules transforming from a diatomic state into smaller hydrogen ions. In addition, these is the danger of atomic hydrogen forming through galvanic corrosion where the process has pipelines made from dissimilar materials.

ABB’s have developed a titanium-based binary nano coating, known as ‘H-Shield‘ to deal with this problem. The coating is applied using the Physical Vapour Deposition (PVD) process; this technique is widely used in a variety of industrial processes to apply high end coatings to metals. The surface of the diaphragm is covered with a protective coating with a uniform thickness throughout. Thanks to the H-Shield’s tight molecular structure it offers the highest level of resistance possible against hydrogen ions permeating the diaphragm, whilst still allowing it to move as pressure conditions change. ABB ran laboratory tests and discovered that the H-Shield offered as much as 20 times the protection against hydrogen permeation than materials such as gold and Hastelloy HC. The H-Shield also performed well in field tests where they withstood conditions where other manufacturers’ transmitters were failing and in need of replacement after 18 to 24 months.

H-Shield was trialled at a Canadian oil refinery, where they process North American and overseas crude oil brought in by ship, rail, and pipeline. The refinery has significant crude storage capacity for crude, intermediate and refined products and can also accommodate liquefied petroleum gas (LPG) in its pressurised storage vessels or tanks. They contacted ABB’s channel partner because they were having problems with hydrogen permeation leading to transmitter failure. An H-Shield 266 DP transmitter with remote seals was supplied and there have been no further problems – the transmitters have been performing precisely and reliably since 2016.

Gold and other precious metals have provided a good level of protection until now. However, new breakthroughs have lead pressure transmitters to perform more effectively in the field, helping organisations to reduce costs and unscheduled downtime and increase productivity.

Digital Edition

PIN 25.6 Buyers' Guide

January 2025

Buyers' Guide Directory - Product Listings by Category - Suppliers Listings (A-Z) Articles Analytical Instrumentation - ASTM D7042: The Quantum Leap in Viscosity Testing Technology -...

View all digital editions

Events

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China

Trinidad and Tobago Energy Conference 2025

Feb 10 2025 Point Lisas, Trinidad

Feb 11 2025 Lagos, Nigeria