Flow meter

New System for Air/Gas Flow Meter Improves Performance and Reduces Maintenance

May 01 2014

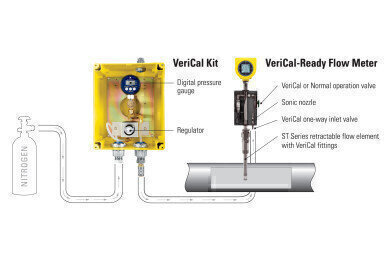

Production and refinery engineers responsible for measuring, monitoring and flaring waste gas will find the advanced ST100 Series Thermal Mass Flow Meter from Fluid Components International (FCI) (USA) with FCI’s VeriCal In-Situ Calibration Verification System combines precise air/gas measurement capability with the convenience of in-situ calibration verification.

A live demo of the ST100 Flow Meter with the VeriCal In-Situ Calibration Verification System will be available at the 2014 Offshore Technology Conference (OTC) in FCI Booth 11500. This industry unique system reduces flow meter operating costs in flare gas applications aboard offshore platforms, at land-based oil/gas facilities and in petrochemical plants.

The ST100 Flow Meter with the VeriCal In-Situ Calibration System is designed to comply with the US Minerals Management Service (MMS) mandate per final rule, 30 CFR Part 250, Subpart K, Section 250, stipulating that all domestic US offshore rigs processing more than an average of 2000 bopd must install flare/vent gas flow meters. These regulations are intended to protect the environment through the monitoring of greenhouse gases (GHG).

Validating flow meter calibration to meet regulatory requirements is no longer labor-intensive, costly or challenging with the VeriCal In-Situ Calibration System. The system verifies flow meter calibration in minutes without removing the meter from the pipe or process. In the past, flow meters had to endure the cost and hassle of being pulled from the process, then returned to the manufacturer or a calibration lab for testing and then shipped back for re-installation.

The ST100 Series Flow Meter sets a new industry benchmark in process and plant air/gas flow measurement, offering the most feature-rich and function-rich electronics available. The ST100’s performance delivers unsurpassed adaptability and value to meet plant gas flow measurement applications for today and tomorrow.

Whether the need is for 4-20 mA analog, frequency/pulse, alarm relays or digital bus communications such as HART, Fieldbus, Profibus or Modbus, the ST100 is the solution. Should a plant’s needs change over time or an upgrade be desirable, the ST100 Flow Meter adapts as necessary with a plug-in card replacement that can be changed out by plant technicians in the field.

The ST100 Flow Meter’s unique graphical, multivariable, backlit LCD display/readout brings new meaning to the term “process information”. It provides the industry’s most comprehensive information with continuous display of all process measurements and alarm status, and the ability to interrogate for service diagnostics.

The user-friendly ST100 stores up to five unique calibration groups to accommodate broad flow ranges, differing mixtures of the same gas and multiple gases, and obtains up to 1000:1 turndown. Also standard is an on-board data logger with an easily accessible, removable 2-GB micro-SD memory card capable of storing 21 million readings.

The comprehensive ST100 Series is comprised of two core model families: ST and STP. ST meters measure both mass flow and temperature, and the exclusive STP family adds a third parameter, pressure, making the ST100 the world’s first triple-variable thermal flow meter. Both families include single-point and dual-element models as configurations.

The ST100 can be calibrated to measure virtually any process gas, including wet gas, mixed gases and dirty gases. The basic insertion style air/gas meter features a thermal flow sensing element that measures flow from 0.25 to 1000 SFPS (0.07 NMPS to 305 NMPS) with accuracy of ±0.75 percent of reading, ±0.5 percent of full scale.

Designed for rugged industrial processes and plants, ST100 Flow Meters include service up to 850ºF (454ºC) and are available with both integral and remote (up to 1000 feet [300 meters]) electronics versions. The ST100 is agency approved for hazardous environments, including the entire instrument, the transmitter and the rugged, NEMA 4X/IP67 rated enclosure. Instrument approvals in addition to SIL-1 include ATEX, IECEx, FM and FMc.

Digital Edition

PIN 25.5 Oct/Nov 2024

November 2024

Analytical Instrumentation - Picturing Viscosity – How Can a Viscometer or a Rheometer Benefit You? - Sustainable Grease Formulations: Evaluating Key Performance Parameters and Testing Method...

View all digital editions

Events

Nov 26 2024 Paris, France

Nov 26 2024 Amsterdam, Netherlands

Nov 27 2024 Istanbul, Turkey

Biogas Convention & Trade Fair 2024

Nov 27 2024 Hanover, Germany

Dec 03 2024 Dusseldorf, Germany