Flow level pressure

Measuring Volumetric Flow by Means of Oscillation

Dec 14 2012

A further measuring process is added to the product range of KOBOLD Messing GmbH (Germany) volumetric flow measurement with a Fluidistor Oscillator. In this measuring procedure, a partial stream of the medium is led into the measuring cell by means of a bypass. In the measuring cell, the medium flows through a chamber with two flow channels. A gate allows the stream to flow through either the left or the right one. On the side of the gate there is a connecting channel which connects both sides. The flow creates overpressure on one side and underpressure on the other. The difference in pressure directs the media stream to the other side. This means that the stream between the two sides starts to oscillate which sets the medium in the connecting channel into vibration. The frequency of the oscillation is directly proportional to the flow speed. A detector determines the oscillation in the connecting channel and converts it into an electrical signal. The signal is processed further in the downstream electronic unit and then displayed or output in another form.

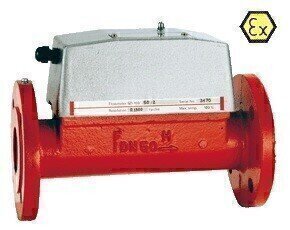

The devices within the DOG product family are designed for tough industrial use. They are offered in flange or intermediate flange versions up to nominal widths DN 400 in gray cast iron, steel and stainless steel.

This means that the equipment can be used for many different applications, from measurement of liquid media of low viscosity, such as for example distilled water, hot water or chemicals up to measurement of gases such as compressed air, natural gas, biogas, fermentation gas, propane, hydrogen gas and many more. Approval by the European ATEX guideline also means that explosive gas streams can be safely measured. As, in contrast to other measuring systems, the oscillation system only requires a low feed pressure and it can also be used in biogas applications where measurement is otherwise extremely difficult.

Generously-dimensioned channels mean that the measuring devices are less prone to dirt deposits. There are no moving parts in the media stream and therefore there is no wear.

The advantages are as follows: reliable performance maintained over long lifetime, high degree of measuring accuracy, not prone to dirt deposits, no wear and large measuring ranges

Whether in district heating systems, general mechanical engineering, waste water technology, heavy industry or the chemical sector: the robust construction of the DOG oscillation flow measurement devices makes them suitable for a wide variety of applications.

Digital Edition

PIN 25.6 Buyers' Guide

January 2025

Buyers' Guide Directory - Product Listings by Category - Suppliers Listings (A-Z) Articles Analytical Instrumentation - ASTM D7042: The Quantum Leap in Viscosity Testing Technology -...

View all digital editions

Events

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China

Trinidad and Tobago Energy Conference 2025

Feb 10 2025 Point Lisas, Trinidad

Feb 11 2025 Lagos, Nigeria