Oil analysis

Fully automated analysis of speciated halogens in pyrolysis oil

Aug 02 2022

Pyrolysis oil, sometimes also known as bio-crude or bio-oil, is a synthetic fuel that can be used as an alternative substitute for petroleum. It is obtained by heating biomass (wood/ algae or even plastics/polymers) in an oxygen-free reactor, at a temperature of about 500 °C with subsequent cooling. Pyrolysis is a well-known and proven technique for the decomposition of organic or non-organic material at elevated temperatures in the absence of oxygen into oil and other constituents. In second-generation biofuel applications—forest and agricultural residues, waste wood, yard waste, and energy crops can also be used as feedstock.

The end product of pyrolysis oil resembles the characteristics of tar and normally contains levels of oxygen too high to be considered a pure hydrocarbon. The high oxygen content results in non-volatility, corrosiveness, immiscibility with fossil fuels, thermal instability, and a tendency to polymerise when exposed to air. As such, it is distinctly different from petroleum products. Removing oxygen from bio-oil or nitrogen from algal bio-oil is known as upgrading and forms a more stable end-product that can be used in pure form or in blends as a fuel alternative.

One of the standard specifications for analysis of pyrolysis biofuel is covered in the ASTM norm D7544-12. This norm only covers the analysis of total sulphur (for combustion analysis), the speciated analysis for halogens (in particular: chloride, fluoride, and bromide) are not mentioned.

A key difference is that nowadays many other waste basis materials like municipal waste, recycling of plastics/polymers, or semi-synthetics are being used to produce pyrolysis oil products. These feed bases may contain fluoride, chloride, and/or bromide and high levels are to be prevented.

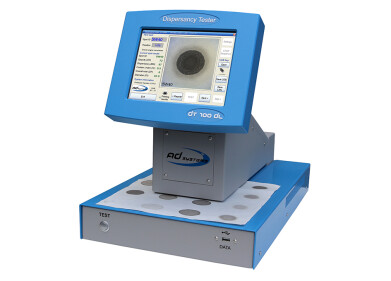

TE Instruments developed a fully automated setup for the analysis of halogens in pyrolysis oils and their feed base. The Xprep C-IC is a compact sample preparation system covering oxidative pyro-hydrolytic combustion, fraction collection, and sample injection towards any ion chromatograph available on the market. The Xprep C-IC can introduce samples via optimised direct injection (liquids module) and/ or via a conventional boat-inlet (boat module) into a horizontal furnace. This automated sample-prep solution reduces the complexity of sample transfer and significantly improves user convenience. Solid sample material can also be introduced into the combustion furnace, via the Newton autosampler with a standard sample capacity of 20 sample positions (extendable up to 60).

Digital Edition

PIN 26.1 Feb/Mar 2025

March 2025

Analytical Instrumentation - Elemental Analysis for Quality and Process Control at Refineries, for Lubricants and Wear Metals in Engine Oils - Synthetic Lubricants: New Developments - Scaling...

View all digital editions

Events

Mar 19 2025 Manila, Philippines

Mar 20 2025 Brussels, Belgium

Mar 20 2025 Guangzhou, China

ACS National Meeting & Expo, Spring 2025

Mar 23 2025 San Diego, CA, USA

Mar 25 2025 Las Vegas, NV, USA

.jpg)

.jpg)

.jpg)