Measurement and testing

Purifying pyrolysis oil derived from mixed plastic waste

Apr 12 2023

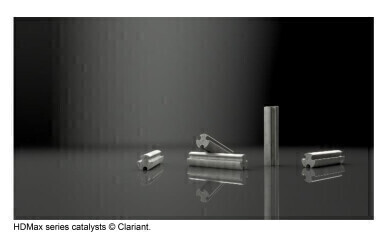

Clariant has launched a flexible and customisable portfolio of solutions for the emerging market of chemical plastics recycling. This new portfolio, which includes HDMax catalysts and Clarit adsorbents, is designed to purify pyrolysis oil that is derived from mixed plastic waste that is hard to recycle. The tailored solutions effectively remove a wide range of contaminants that continuously change in the feed, making them flexible and adaptable to any process configuration. In addition to these products, Clariant also offers operational assistance from startup to process optimisation, which lasts throughout the lifetime of the product.

The result of using these new products is a highly efficient removal of impurities, allowing producers to achieve pyrolysis oil that is compatible with ethylene plants. Pyrolysis oil is created from a chemical recycling process that breaks down polymers into basic building blocks to be used for new feedstock streams. This process helps reduce the environmental burden created by plastic waste that would otherwise be incinerated or landfilled, enabling a circular value chain for the production of base chemicals.

Jens Cuntze, President of Catalysts at Clariant, said, "As we support our customers' move towards a more circular economy with alternative feedstock sources, the development of more sustainable catalyst technologies is crucial.”

Digital Edition

PIN 25.6 Buyers' Guide

January 2025

Buyers' Guide Directory - Product Listings by Category - Suppliers Listings (A-Z) Articles Analytical Instrumentation - ASTM D7042: The Quantum Leap in Viscosity Testing Technology -...

View all digital editions

Events

Jan 20 2025 San Diego, CA, USA

Jan 22 2025 Tokyo, Japan

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China