Elemental analysis

State-of-the-art elemental analyser provides precise carbon and sulphur determination for energy sector and a host of other demanding industries

Oct 02 2023

Mol Analytik GmbH’s CS1000 elemental analyser provides a perfect solution to accurately determine carbon and sulphur content in solid, mainly organic samples. This advanced instrument offers peace-of-mind elemental analysis across a wide range of industries, including energy generation, refineries, the chemical sector, thermal power plants, coal and mining, foundries, environmental monitoring, recycling plants, and the cement industry.

The CS1000 elemental analyser has the capability to characterise a wide range of solid, mainly organic samples, ranging from oil, rubber, waste to ash, bauxite, soil, catalysts, ceramics, plastic, coal, coke, soot, sand, slag, and clay. In industries where product quality and chemical composition are of utmost importance, such as mining, geology, and coal, this analyser plays a central role in ensuring precision and reliability.

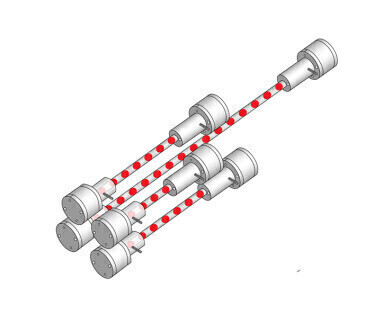

The instrument’s operational principle is based around generating gases, including CO2 H2O, and SO2, during the sample combustion process which undergo meticulous cleaning and moisture removal before detection by use of non-dispersive infrared (NDIR) detectors. The flexible analyser accommodates up to four independent, selective wide-range infrared detectors which can be configured according to the end-user's specific requirements. Results are then calculated and reported based on sample weight using specialised software.

The CS1000 operational reliability is based on the absorption of infrared light by gases. Each gas has a distinct spectral absorption pattern which is intricately linked to the number and type of atoms in the gas molecules. Mol Analytik have integrated modulable infrared emitters that enable rapid temperature cycling and are significantly more powerful and cost-effective than the incandescent emitters ubiquitous to conventional gas spectroscopy.

The modulable infrared emitter emits narrow-band, pulsating infrared light; these are crystal-controlled for frequency stability. The infrared light passes through the measuring cuvette which contains the measuring gas/carrier gas mixture. Depending on the composition of the gas mixture, only specific infrared spectrum frequencies are absorbed, with absorption intensity correlating with gas concentration. The infrared beam will then reach a semiconductor infrared detector, which emits an electrical signal which is proportional to the radiation intensity. When the infrared light pulsates, the semiconductor infrared detector will output an alternating signal, compensating for temperature, aging effects and noise. Downstream electronics amplify and rectify the signal, presenting it as direct voltage at the non-dispersive infrared (NDIR) detector's output.

The CS1000, as well as all high-temperature furnaces in the Mol Premier® series, can be operated with central evaluation and control software, available in over 80 different languages for user accessibility across the globe.

Digital Edition

PIN 25.6 Buyers' Guide

January 2025

Buyers' Guide Directory - Product Listings by Category - Suppliers Listings (A-Z) Articles Analytical Instrumentation - ASTM D7042: The Quantum Leap in Viscosity Testing Technology -...

View all digital editions

Events

Jan 25 2025 San Diego, CA, USA

SPE Hydraulic Fracturing Technology Conference and Exhibition

Feb 04 2025 The Woodlands, TX, USA

Feb 05 2025 Guangzhou, China

Trinidad and Tobago Energy Conference 2025

Feb 10 2025 Point Lisas, Trinidad

Feb 10 2025 Lagos, Nigeria